Harrietsfield Williamswood Community Centre

This case study, submitted by the ReCover Initiative, outlines a net-zero scenario using a panelized deep retrofit solution for a community centre built in 1970.

| Building Type | Part 3 | Location | Halifax, NS |

| Year Built | 1970 | Structure Type | Concrete block walls and wood framed roof |

| Post-Retrofit Total Floor Area | 580m2 | Climate Zone | 6 |

| Heating Degree Days | 4000 |

Project Team

- Habit Studio ( Designer or Architect )

- RDH ( Energy Modelling )

- M&R Engineering ( Mechanical & Electrical Engineer )

- Stanley Francispillai ( Hygrothermal )

- Seefar Building Analytics ( Financial Model )

- QSolv ( Cost Consultant )

- Fatma Osman ( Embodied Carbon Modelling )

- Natural Resources Canada, The Atmospheric Fund, Nova Scotia Department of Natural Resources and Renewables, City of Burlington, Municipality of Colchester, Halifax Regional Municipality, Town of New Glasgow, City of Oakville, City of Saskatoon ( Funders )

Project Priorities

- Reduce Energy Consumption

- Achieve Net Zero or Net Zero Ready

- Reduce GHG Emissions

- Other

Project Goals

The objectives of this study were to de-risk investment in deep retrofits in Canada, to provide evidence on the effectiveness and scalability of a panelized deep retrofit approach and to build confidence and experience in deep retrofits among Canadian municipalities and industry stakeholders.

The goals for the Deep Retrofits explored included:

- Develop a scenario that achieves an Energy Use Intensity (EUI) reduction of 50%.

- Develop a Net Zero Energy Ready (NZER) scenario.

- Develop a Net Zero Energy (NZE) scenario with the addition of onsite renewables.

- All solutions minimize occupant disruption during construction.

- All solutions target minimal embodied carbon.

- Identify the retrofit pathway to the lowest Total Cost of Building Ownership.

- Demonstrate a calculated payback of 20 years or better.

Project Description

Planning the Retrofit

Existing Building Details

Overview

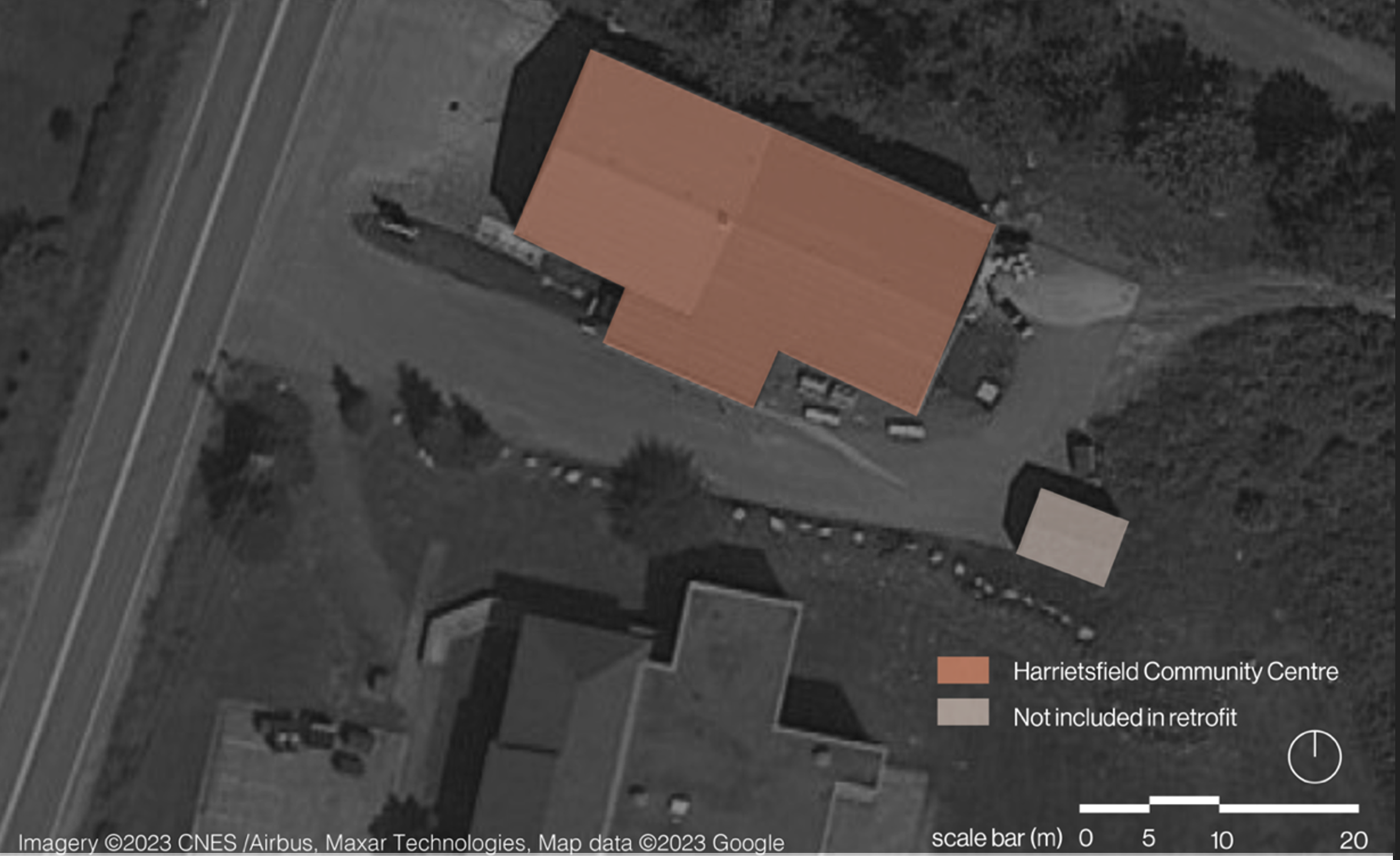

The Harrietsfield Williamswood Community Centre is a two-storey building with a gross floor area of 581m2 (6,256sq. ft).

The upper level of the building contains a day care centre which operates an after-school program and full day programs during summer and March Break. The facility includes a multipurpose room which is used for community recreation services including fitness classes, meetings, art classes and workshops and for private event rentals. Daily hours of operation are 10am – 9pm during the school year and 7:30am – 6:00pm in summer. The typical occupancy of the daycare is 50 people and occupancy of the multipurpose room varies, with an average of 150 people for events.

The building was originally a fire station estimated to have been constructed in 1970. It was converted to its current use in a major renovation in 1994. HRM has implemented several efficiency measures to the building including adding heat pumps (2015), LED lighting upgrades (since 2013) and a wall mounted solar air heater (2011).

The facility has been operated in partnership with the Harrietsfield Williamswood Community Centre Association (HWCCA) since 2010. Capital work on the building, including major repairs and maintenance of mechanical and electrical systems are the responsibility of HRM while utility costs are paid by the HWCCA.

Existing Envelope

The main walls of the building are concrete block with interior 2×6 stud cavity walls offset from the concrete 100mm (4”) and insulated with fiberglass batt. The lower-level bump out walls are 2×6 framing with fiberglass batt. Openings from three former overhead doors on the west wall have been infilled with wood framing and fiberglass batt. The building is clad with fiber cement siding, with a small area of brick framing the former door openings. The windows are double glazed with vinyl frames.

The roof is framed with wood trusses and insulated with approximately 200mm (8”) of loose cellulose at the ceiling plane. There appears to be a polyethylene vapour barrier installed in the walls and roof. Given the building’s age, this is unlikely to be continuous.

The concrete slab-on-grade floors are believed to be uninsulated.

Existing Structure

The foundation consists of concrete foundation walls and strip footings. No structural deficiencies are apparent in visible portions of the foundation and there is no evidence to suggest deficiencies in the buried portions.

The above-grade walls are 150mm (6”) concrete masonry unit (CMU) block. These are the main load-bearing elements and the primary lateral load resisting system. The team was unable to confirm the presence of grout or steel reinforcing in the CMU voids. There is no evidence to suggest structural deficiencies in the wall system.

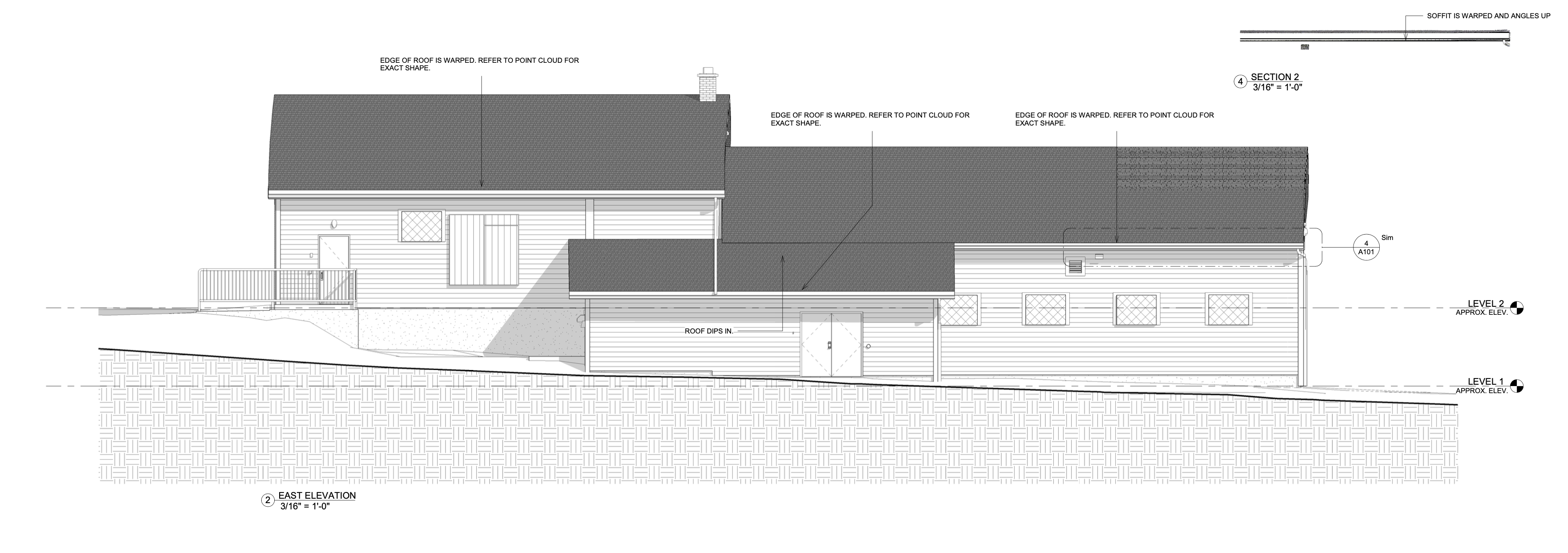

The roof structure is pre-engineered timber trusses with tongue and groove plank decking. The connection detail between the trusses and walls could not be verified during the site visit. It is assumed that the trusses bear on either a double top plate or a nailer on the CMU block walls.

The roof trusses are leaning, with the truss ridge approximately 25mm (1”) east relative to the bottom chord of the truss. This issue wasn’t identified in the 2013 Building Condition Assessment (Appendix B). A roof leak was also identified, by an employee of the daycare. This has anecdotally been present since Hurricane Dorian in September 2019.

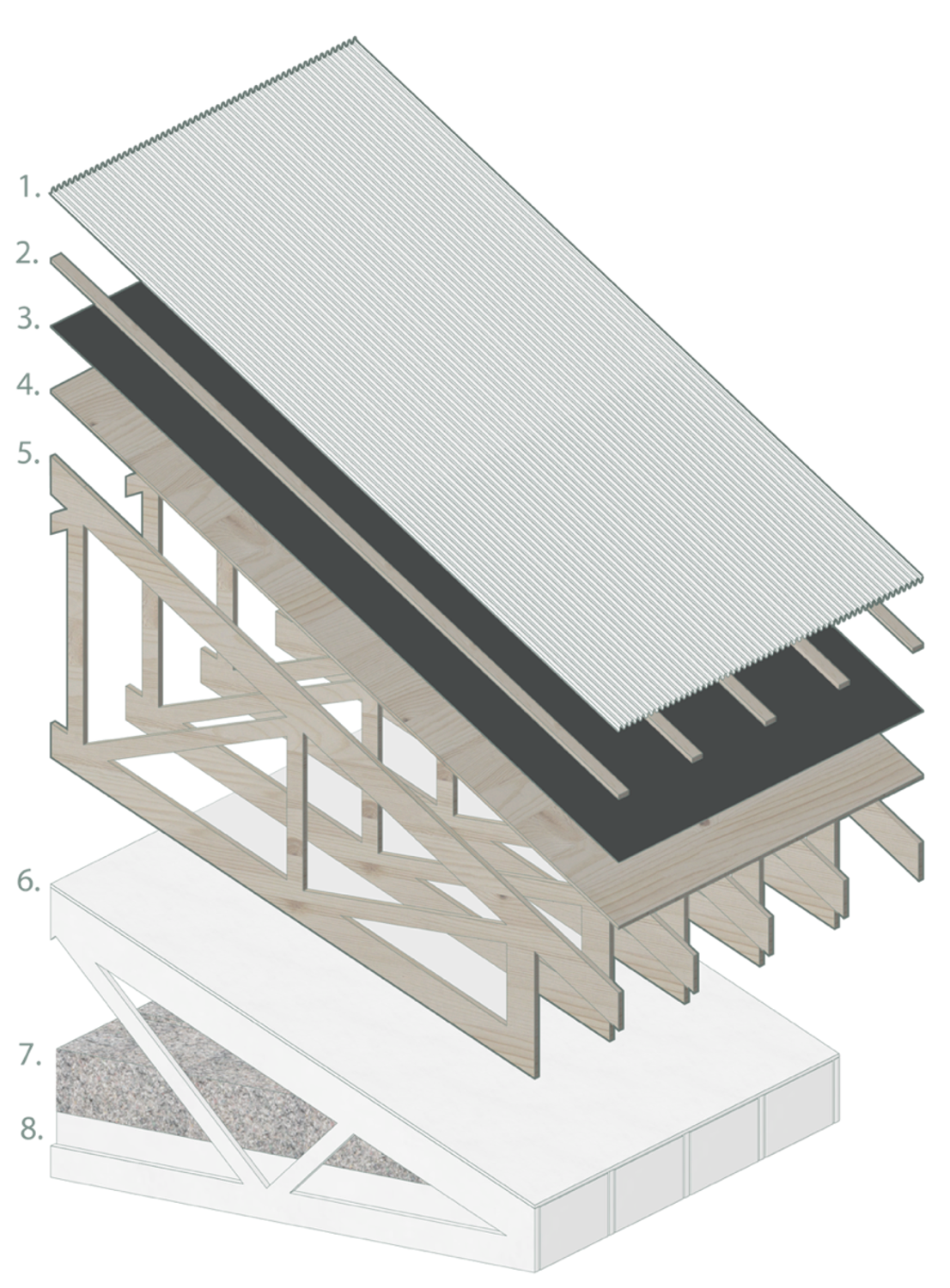

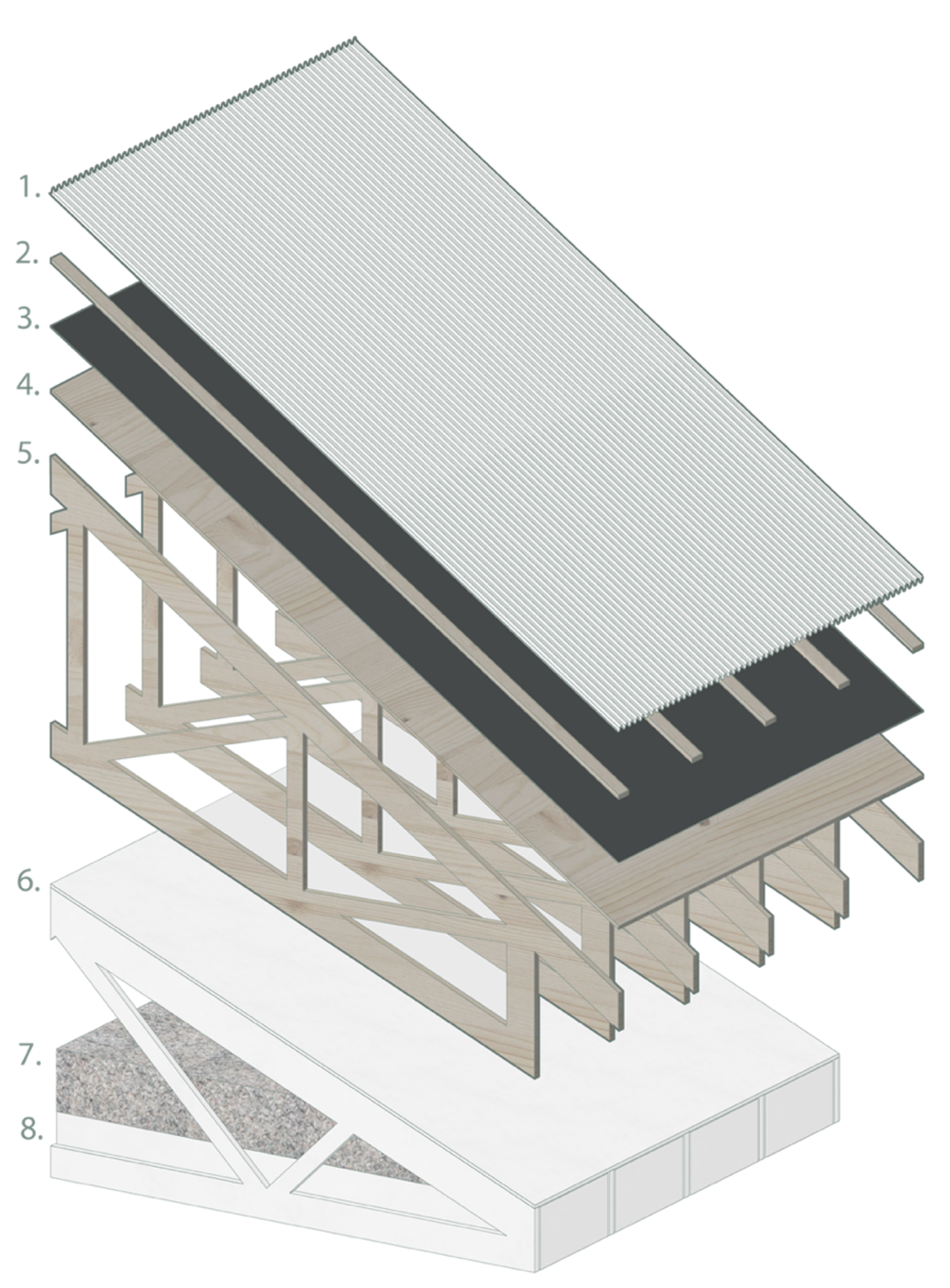

The existing roof structure was determined to be inadequate to support existing loads. Alterations must be independent of the existing roof trusses. Existing roof structure

Existing Electrical and Mechanical

| Primary Heat Source | Oil Fired Boiler |

| Heat Distribution | Hydronic Baseboard |

| Cooling Source | Mini Split Heat Pumps |

| Electrical Service | 100A and 200A connection to grid |

| Electrical Distribution | 1P, 240V, 100A breaker panel and 1P, 240V, 200A breaker panel |

| Interior Lighting | Recently upgraded LED |

Existing Energy Use (KWH/M2/YR)

| Lights | 17.68 |

| Plug Loads | 9.68 |

| Electric Heat | 6.20 |

| Cooling | 0.80 |

| Pump | 1.27 |

| Fans | 1.93 |

| Elec DHW | 11.18 |

| Fuel Oil | 96.23 |

Net Zero Scenario

The design team worked collaboratively to develop retrofit scenarios targeting the project objectives. The analysis assumes a ‘like for like’ retrofit where space usage, occupancy schedules, internal geometry, volume of conditioned space, and window and door dimensions and locations are consistent with existing conditions.

The strategy for building enclosure upgrades is to retrofit the walls with prefabricated ReCover panels. The proposed roof retrofit involves removing existing metal roofing and insulation and replacing it with lightweight vacuum insulated panels (VIPs) and replacing the metal roof.

| Existing Building | Min + Solar | |

|---|---|---|

| Effective Wall R-Value | R12 | R24 |

| Effective Roof R-Value | R24 | R35 |

| Windows | Vinyl, Double Glazed, R2.5 | Triple Pane R5.56 |

| Air Tightness | 2.3 L/s m² | 0.5 L/s m² |

| Heating Source | Oil Fired Boiler | Electric Boiler (Primary Heat Source) |

| Heating Distribution | Hydronic Baseboard, Mini Splits, Solar Wall Air Heater | Hydronic Baseboards, Existing + 2 New Mini Split Units |

| Cooling | 2 Mini Splits | Existing + 2 New Mini Split Units |

| DHW | Coil Boiler and Electric Water Heater | Existing Electric Water Heater |

| Ventilation Equipment | None | 90% SRE ERVs |

| Electrical Service | 100A and 200A | Combined 400A |

| Renewable | None | 69 kW Solar PV |

| 60 Year TCBO | $4,916,548 | $3,102,000 |

Panelized Solutions

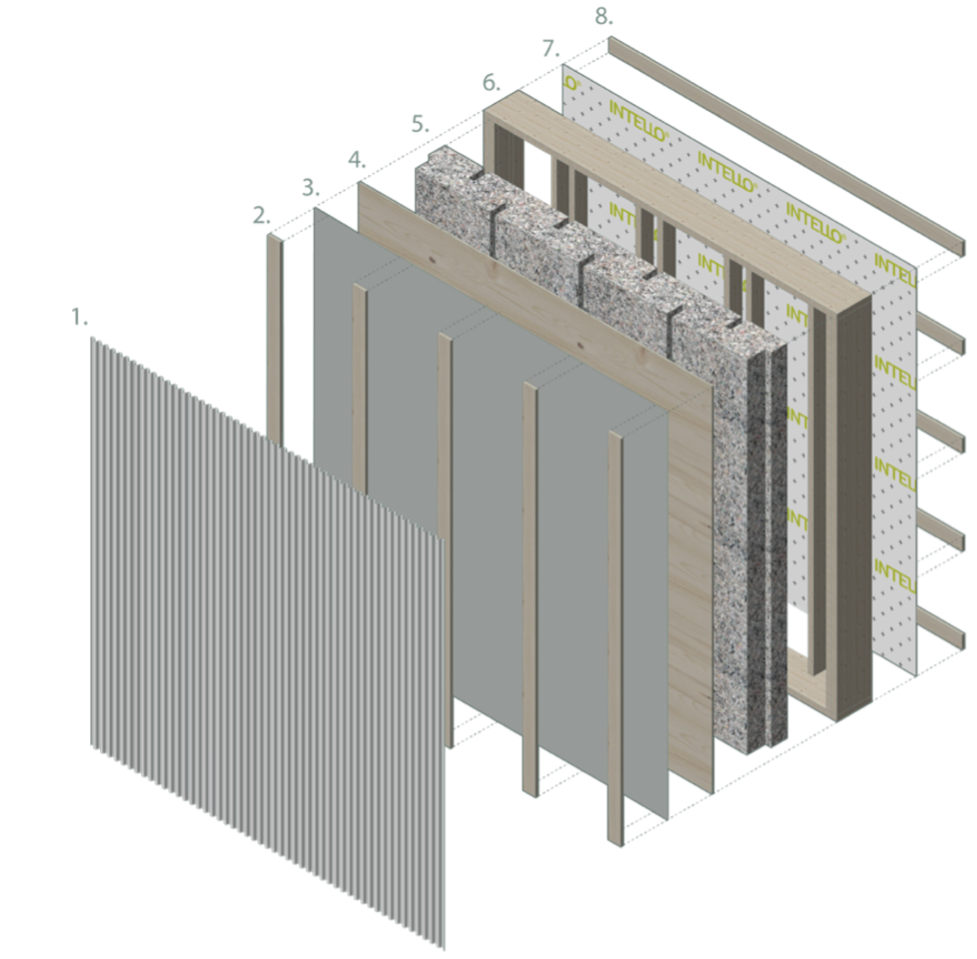

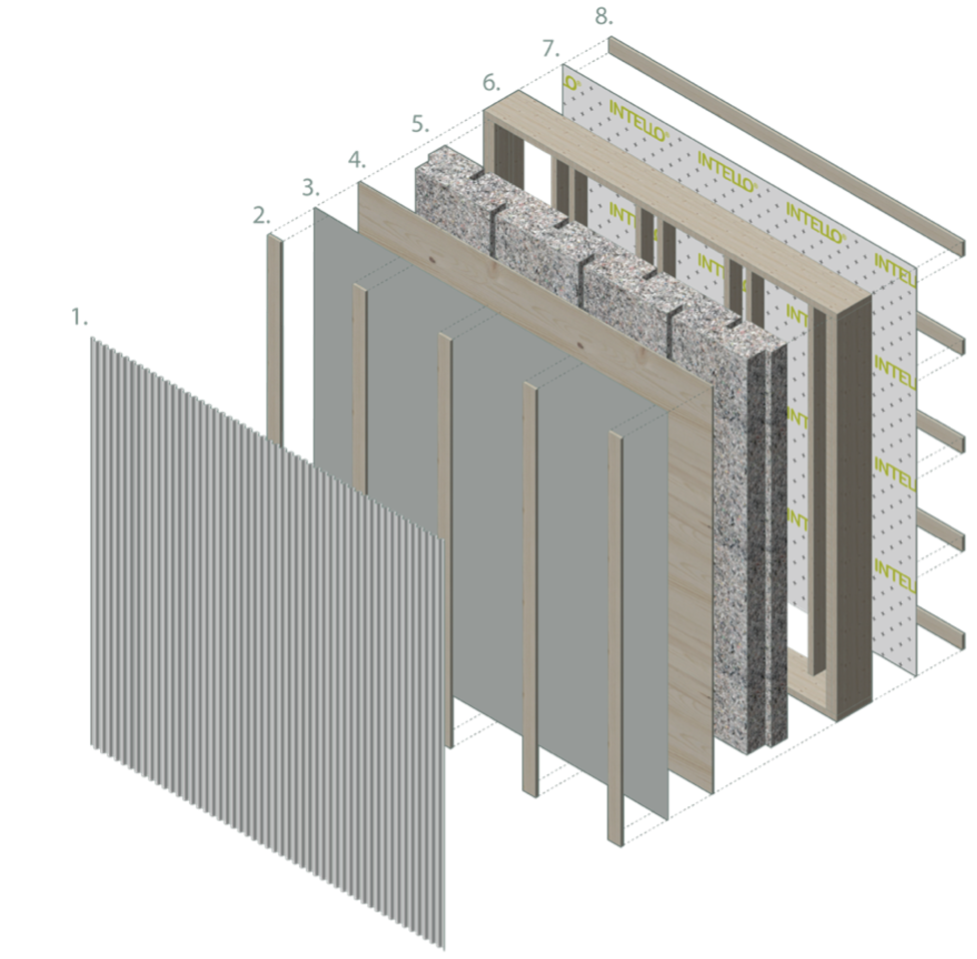

The prototype ReCover panel is a wood framed box which holds carbon storing cellulose insulation. The depth of the frame is flexible depending on the needed performance.

The panel components were specified to minimize moisture risks by shedding precipitation on the outside and by promoting drying activity to the exterior through the panel assembly. This is important as the existing assemblies include vapour retarding materials, including polyethylene vapour barrier and rigid foam insulation, which will inhibit drying to the interior of the building. These materials will also inhibit outward vapour drive, from the interior into the panels, however given the age and condition of the building it is highly unlikely that these materials comprise a continuous vapour barrier. The panels are be designed to promote any moisture movement that occurs from the interior to dry to the exterior.

Strapping on the interior side of the panel permits fitting adjustments against the existing walls and provides an internal air cavity that serves as a moisture buffer space for vapour diffusion from the inside to pass out through the panels. The frame backing layer is a “smart” vapour control membrane which varies in permeability depending on the relative humidity of its environment. If moisture is present between the panel and the existing walls the membrane fibers open to let moisture escape. Wood panel framing, plywood sheathing and cellulose insulation are all hygroscopic materials, meaning their fibers transport moisture from areas of higher humidity to those of lower humidity. A vapour-open water-resistive barrier (WRB) protects the outer plywood sheathing and provides a drainage plane behind the rainscreen cavity and metal siding.

Wall Panel Details – PDF | Wall Panel Details – Sketchup

Embodied Carbon

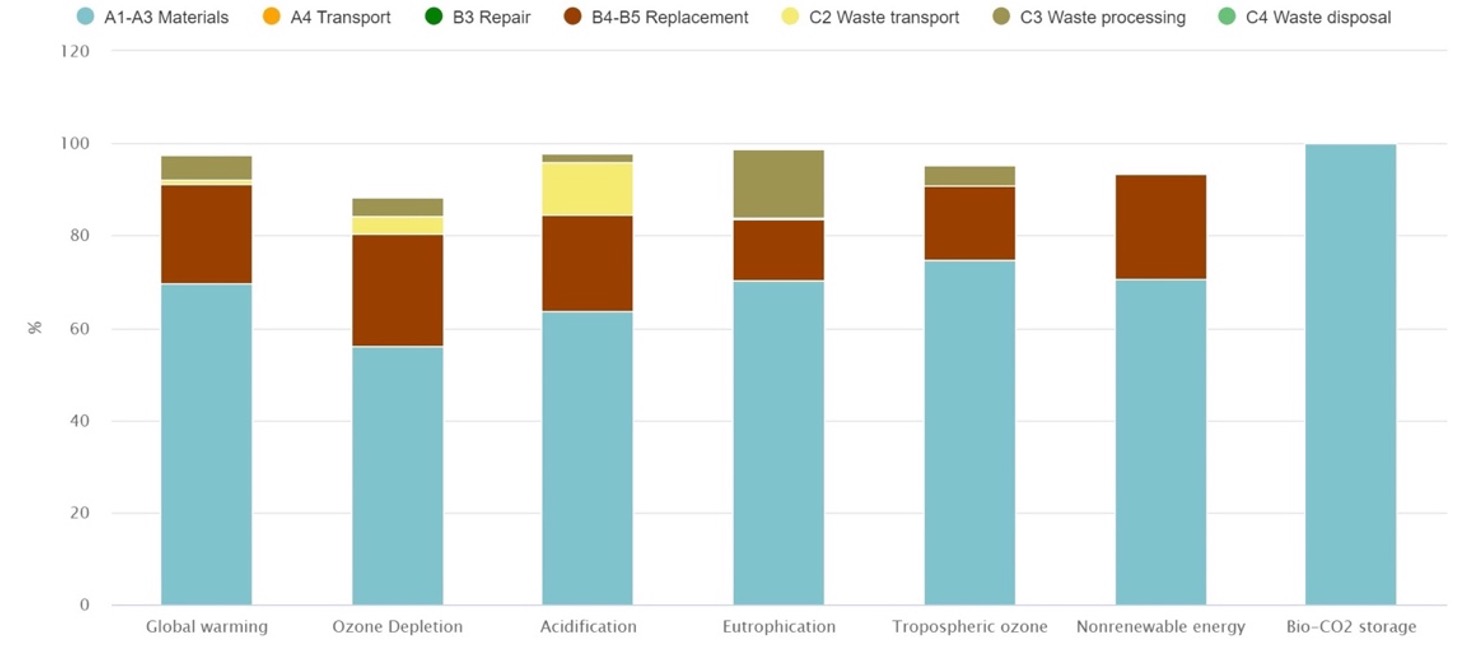

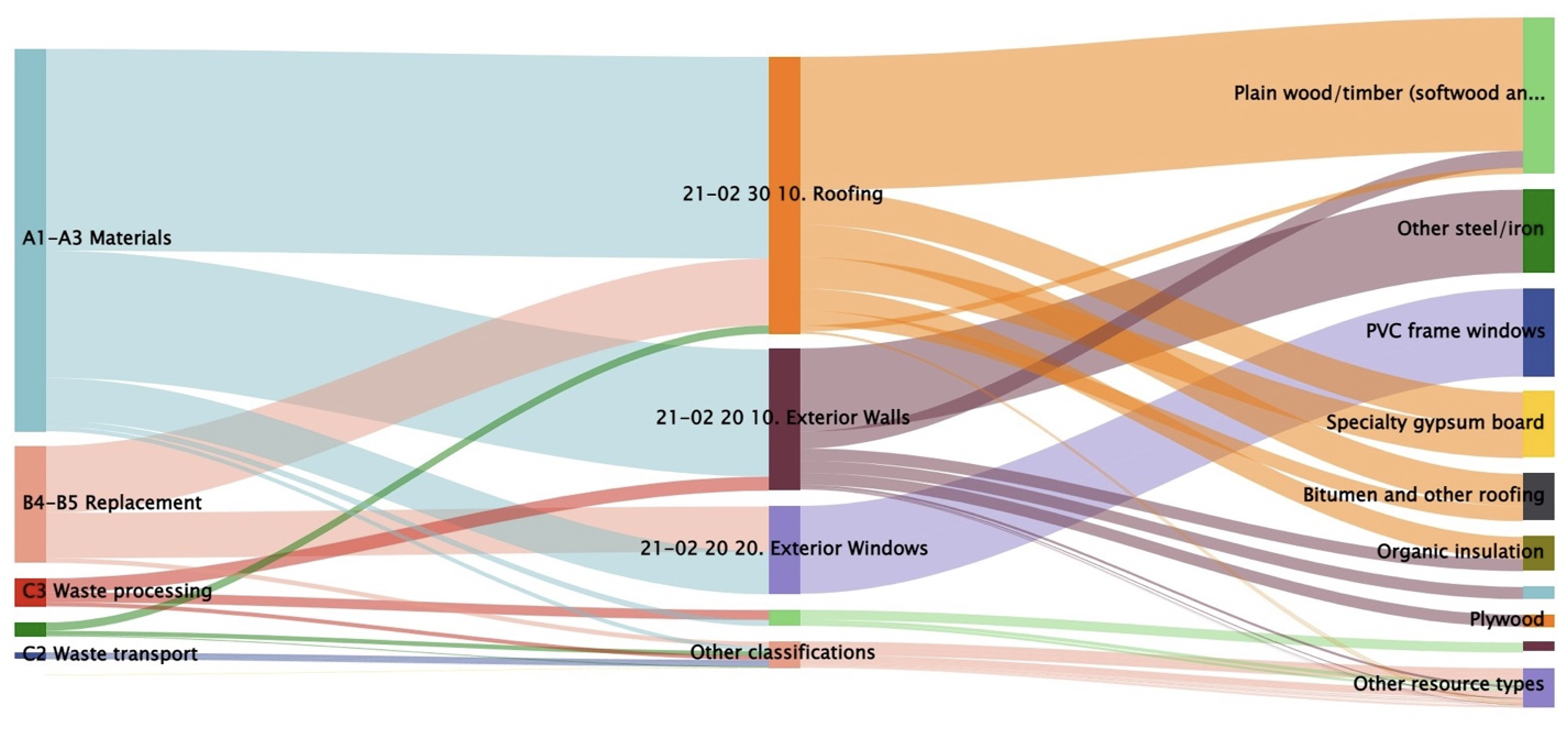

Embodied Carbon was modeled for this project in One Click LCA. Materials modeled were based on the most representative materials available to the Canadian market with Environmental Product Declarations (EPDs) available in the One Click LCA database. The analysis was limited to embodied carbon of assembly materials being added to the building including panel additions to above-grade walls, roofs, below-grade components, and windows and doors. HVAC and electrical components were excluded from the analysis.

The results include a whole life cycle assessment of the building in six impact categories: Global Warming, Ozone Depletion, Acidification, Eutrophication, Formation of tropospheric ozone, Depletion of nonrenewable energy, and Biogenic carbon storage.

View Embodied Carbon Graph 1 |

View Embodied Carbon Graph 2

Total Cost of Building Ownership (TCBO)

Total Cost of Building Ownership (TCBO) analysis was conducted using the Sustainable Energy Efficient Facility Asset Renewal (SEEFAR)-Valuation© program. Calculations include costs for utilities, insurance, carbon tax, maintenance, maintenance capital (replacing major components as they age out), interest, and escalation of these costs over time. TCBO analysis typically includes property taxes, however the building is not subject to property tax.

TCBO Summary

| Base Case | Min + Solar | |

|---|---|---|

| GHG Emissions (kg) (60 Years) | 1,854,060 | 0 |

| EUI (kWh/m²/year) | 146.0 | 0.0 |

| TCBO at 60 Years | $4,917,000 | $3,102,000 |

| TCBO Savings at 60 Years | $0 | $1,815,000 |

| % Diff. from Base Case | – | 37% |

Cumulative TCBO

The cumulative total cost of building ownership becomes cheaper than business as usual after 39 years.