Burlington Seniors Centre Retrofit – Feasibility Study

This feasibility study, submitted by the ReCover Initiative, outlines a net-zero scenario using a panelized deep retrofit solution for a seniors centre in Saskatoon, SK.

| Building Type | Part 3 | Location | Burlington, ON |

| Post-Retrofit Total Floor Area | 2000m2 | Climate Zone | 5 |

| Heating Degree Days | 3740 |

Project Team

- Habit Studio ( Building Science Advisor )

- RDH ( Energy Modelling )

- M&R Engineering ( Mechanical & Electrical Engineer )

- Seefar Building Analytics ( Financial Model )

- Stanley Francispillai ( Hygrothermal )

- QSolv ( Cost Consultant )

- Fatma Osman ( Embodied Carbon modeling )

- Natural Resources Canada, The Atmospheric Fund, Nova Scotia Department of Natural Resources and Renewables, City of Burlington, Municipality of Colchester, Halifax Regional Municipality, Town of New Glasgow, City of Oakville, City of Saskatoon ( Funder )

Project Priorities

- Reduce Energy Consumption

- Achieve Net Zero or Net Zero Ready

- Reduce GHG Emissions

- Other

Project Goals

The objectives of this study were to de-risk investment in deep retrofits in Canada, to provide evidence on the effectiveness and scalability of a panelized deep retrofit approach and to build confidence and experience in deep retrofits among Canadian municipalities and industry stakeholders.

The goals for the Deep Retrofits explored included:

- Develop a scenario that achieves an Energy Use Intensity (EUI) reduction of 50%.

- Develop a Net Zero Energy Ready (NZER) scenario.

- Develop a Net Zero Energy (NZE) scenario with the addition of onsite renewables.

- All solutions minimize occupant disruption during construction.

- All solutions target minimal embodied carbon.

- Identify the retrofit pathway to the lowest Total Cost of Building Ownership.

- Demonstrate a calculated payback of 20 years or better.

Project Description

Planning the Retrofit

Existing Building Details

Overview

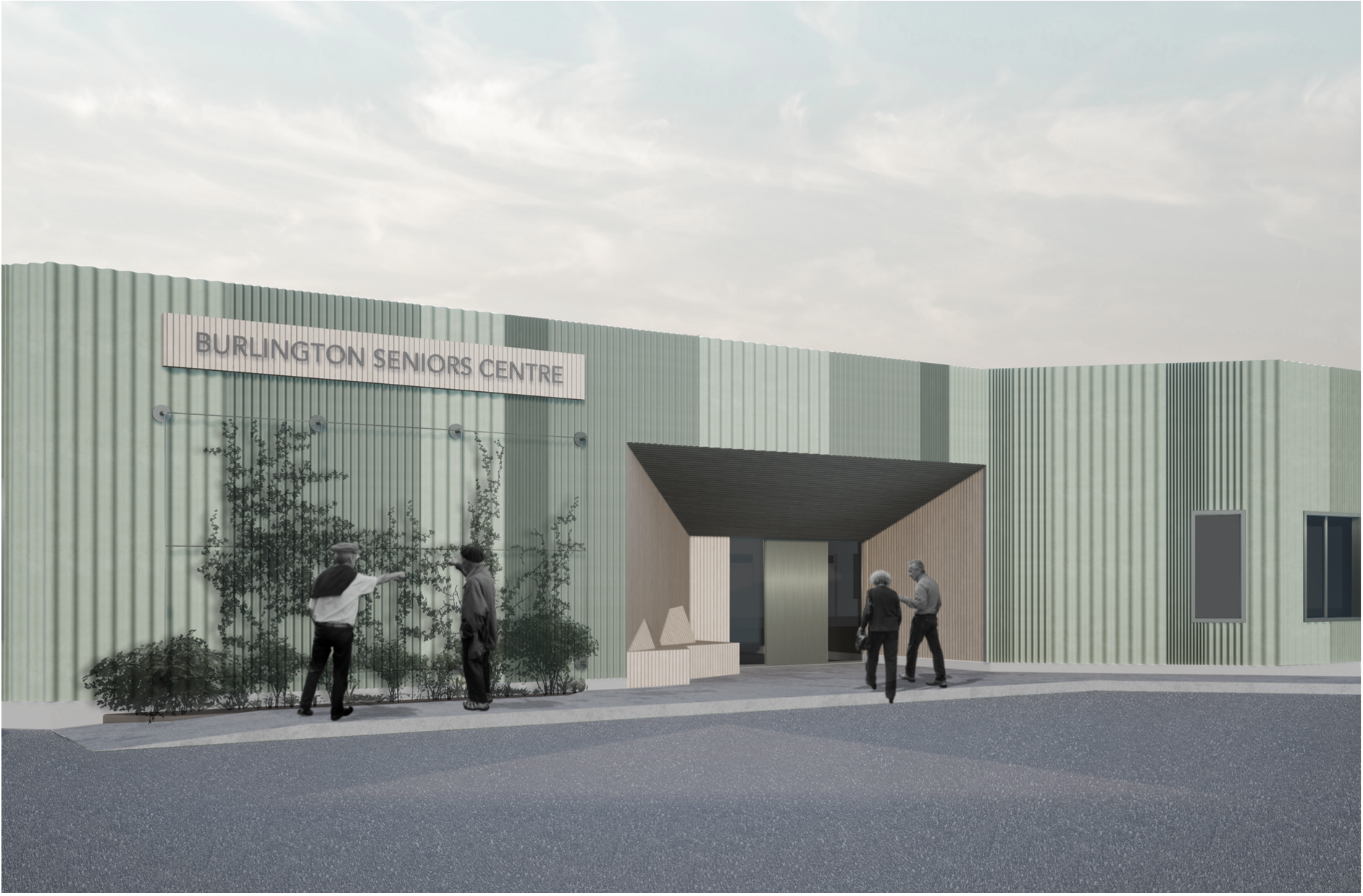

The Burlington Seniors Centre is a one storey structure with a gross floor area of 2,000m2 (21,526 sq.ft.). Its footprint is irregularly shaped with many 135-degree angles. The original building was built in 1979 and it underwent a renovation and expansion in 2005.

The Burlington Seniors Centre offers a variety of recreation services for people aged 55 and older, including fitness and art classes, social events, church services, and workshops. It is also rented out for events such as parties, meetings, and trade shows. The facility is open year-round from 7am to 10pm on weekdays and 8:30am to 4:30pm on weekends. The space is well used with programing offered most days continuously between 8:30am to 9pm. As services are offered both on a pre-registered and a drop-in basis, the number of daily visitors to the facility fluctuates. The building also contains administration offices, a 420m2 (4,500 sq. ft) auditorium and a commercial kitchen. Prior to the pandemic the kitchen served breakfast and lunch through the week, however currently the kitchen prepares only baked goods and drinks.

The Burlington Seniors Centre is located at 2285 New Street, Burlington, Ontario. It is one of several recreation facilities in Burlington’s Central Park, an activity hub located less than a kilometer inland from Lake Ontario. The building is surrounded by sports fields, gardens, a library, theatre, an arena and more.

Southern Ontario has a humid continental climate and experiences periods of high heat and humidity in summer. The region is expected to experience continued temperature increases in both summer and winter and higher annual precipitation. The site is in Canadian building code climate zone 5.

The City of Burlington is working towards being a net carbon zero community by 2050.

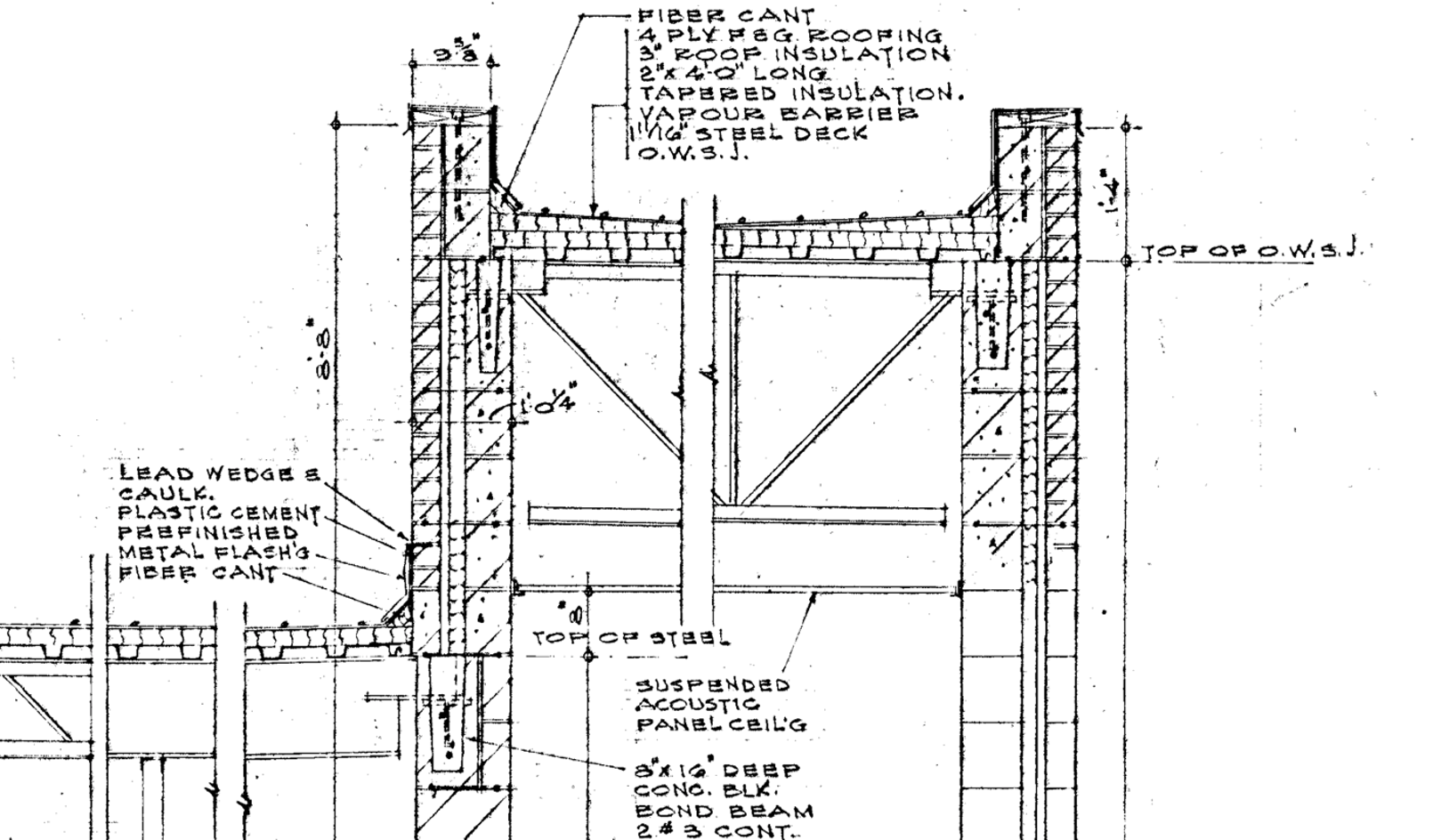

Existing Envelope

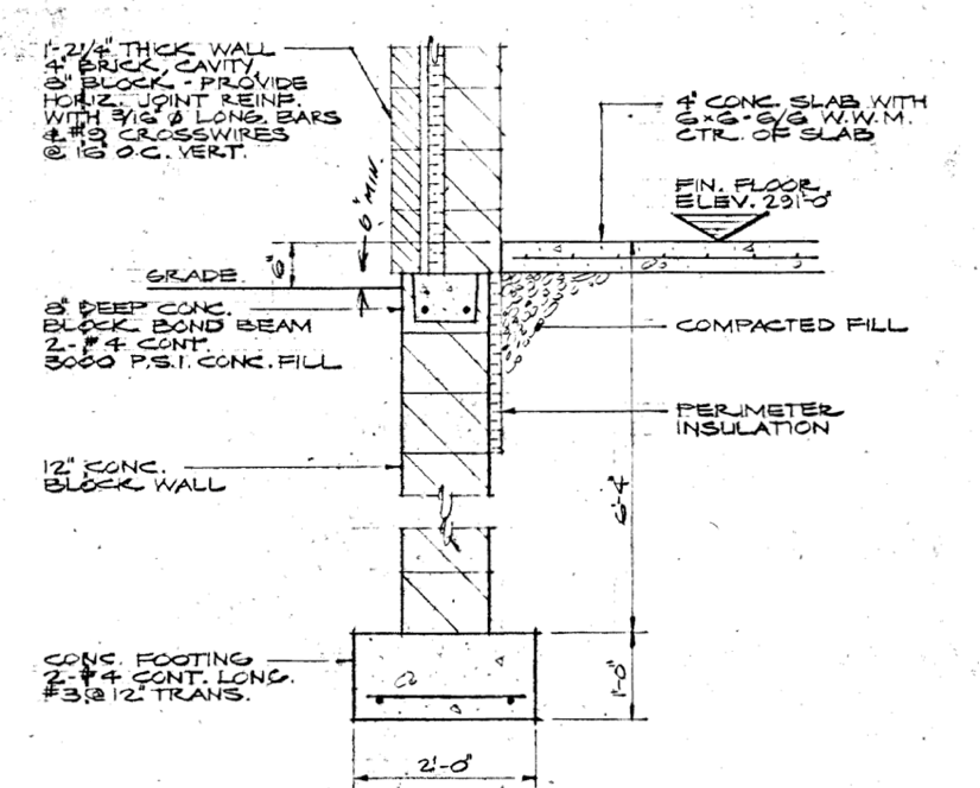

The walls are assumed to be insulated with 50mm (2”) extruded polystyrene (XPS) insulation between the brick cladding and concrete block. Phenolic panel accent walls are assumed to have 75mm (3”) of XPS insulation. The original drawings show 50-75mm (2”- 3”) of roof insulation beneath a layer of tapered insulation. This is also assumed to be extruded polystyrene (XPS) based on the 2017 Roof Condition Assessment. The concrete floor slab is shown as uninsulated in the original building and the addition drawings show slab insulation at the perimeter only.

Assumptions were made where references in original documents were unspecific, for example existing roof drawings reference ‘roof insulation’ but do not state the type and walls show insulation but do not note it in the assembly.

Existing Structure

The foundation and above grade wall structure are 200mm and 305mm (8” and 12”) concrete masonry unit (CMU) blocks installed on cast-in-place concrete strip footings. There is capacity in the masonry walls to accommodate additional loading.

The roof structure is a system of pre-engineered open web steel joists (OWSJs) bearing on the CMU walls. Specifics of the steel strength were not available.

There is no evidence to suggest structural deficiencies in the structure of the building, however confirmation of the wall condition through selective destructive testing is recommended prior to panelized over-cladding.

The results of structural assessment are that the existing walls are suitable for a panelized retrofit but that adding prefabricated panels is not viable for the roofs.

Existing Electrical and Mechanical

| Primary Heat Source | Natural Gas RTU |

| Heat Distribution | Ducted VAV/CAV and electric baseboard |

| Cooling Source | Ducted VAV/CAV and Mini Split Heat Pumps |

| Electrical Service | 400A connection to grid |

| Electrical Distribution | 600V, 400A breaker panel and several 120-208V sub-panels |

| Interior Lighting | Mostly Fluorescent |

Existing Energy Use (KWH/M2/YR)

| Lights | 47.29 |

| Plug Loads | 41.74 |

| Electric Heat | 45.84 |

| Cooling | 24.20 |

| Pump | 1.44 |

| Fans | 24.93 |

| Elec DHW | – |

| Natural Gas Heating | 218.84 |

| Natural Gas Hot Water | 31.14 |

Upgrade Scenario

The design team worked collaboratively to develop retrofit scenarios targeting the project objectives. The analysis assumes a ‘like for like’ retrofit where space usage, occupancy schedules, internal geometry, volume of conditioned space, and window and door dimensions and locations are consistent with existing conditions.

The strategy for building enclosure upgrades is to retrofit the walls with prefabricated ReCover panels and to complete a conventional retrofit to the roof by adding outboard rigid insulation as a panelized roof retrofit is not structurally viable.

Energy conservation measures for the following four scenarios were developed:

- Minimum Upgrade Scenario targeting a 50% reduction in TEUI from the baseline.

- NZER – ASHP targeting a 75% reduction in TEUI from the baseline.

- NZER – GSHP targeting a 75% reduction in TEUI from the baseline.

- Net Zero Energy (NZE).

Building enclosure upgrades were developed for each scenario with post-retrofit airtightness targeting 0.5 L/s·m2, a 75% reduction from the estimated existing air infiltration. All scenarios propose upgrading to high performance windows.

Mechanical and electrical retrofits were developed based on ease of integration with existing systems and installation cost. As the building has a high occupant density, the heating and cooling systems were designed around the cooling loads.

For the NZER scenarios, both air source heat pumps (ASHP) and ground source heat pumps (GSHP) were considered in the design analysis. A GSHP is more energy efficient than an ASHP, however the capital costs of installing an GSHP system are typically much higher. Depending on the specific building details it is not immediately apparent which option is the better investment. The Net Zero Energy scenario is based on the GSHP option which resulted in the lowest TCBO.

| Existing Building | Net Zero Energy | |

|---|---|---|

| Effective Wall R-Value | R7 | R25 |

| Effective Roof R-Value | R21 | R60 |

| Windows | Aluminum, Double Glazed, R2.5 | Triple Pane R5.56 |

| Air Tightness | 3.0 L/s m² | 0.5 L/s m² |

| Heating Source | Natural Gas RTU | Ground Source VRF |

| Heating Distribution | Ducted VAV/CAV and electric baseboard | Ducted Fan Coil Units |

| Cooling | Ducted VAV/CAV and Mini Split Heat Pumps | Existing + 2 new Mini Split Units |

| DHW | Natural Gas Tankless Water Heater | HP Water Heater |

| Ventilation Equipment | Ducted VAV/CAV | 90% SRE ERVs |

| Electrical Service | 600V, 400A breaker panel and several 120-208V sub-panels | Existing 600V service, 400A breaker panel (new), 400A main breaker, 3P, 208V panel for mechanicals, and several 120-208V sub-panels |

| Renewable | None | 220kW PV |

| 60 Year TCBO | $34,646,000 | $24,430,000 |

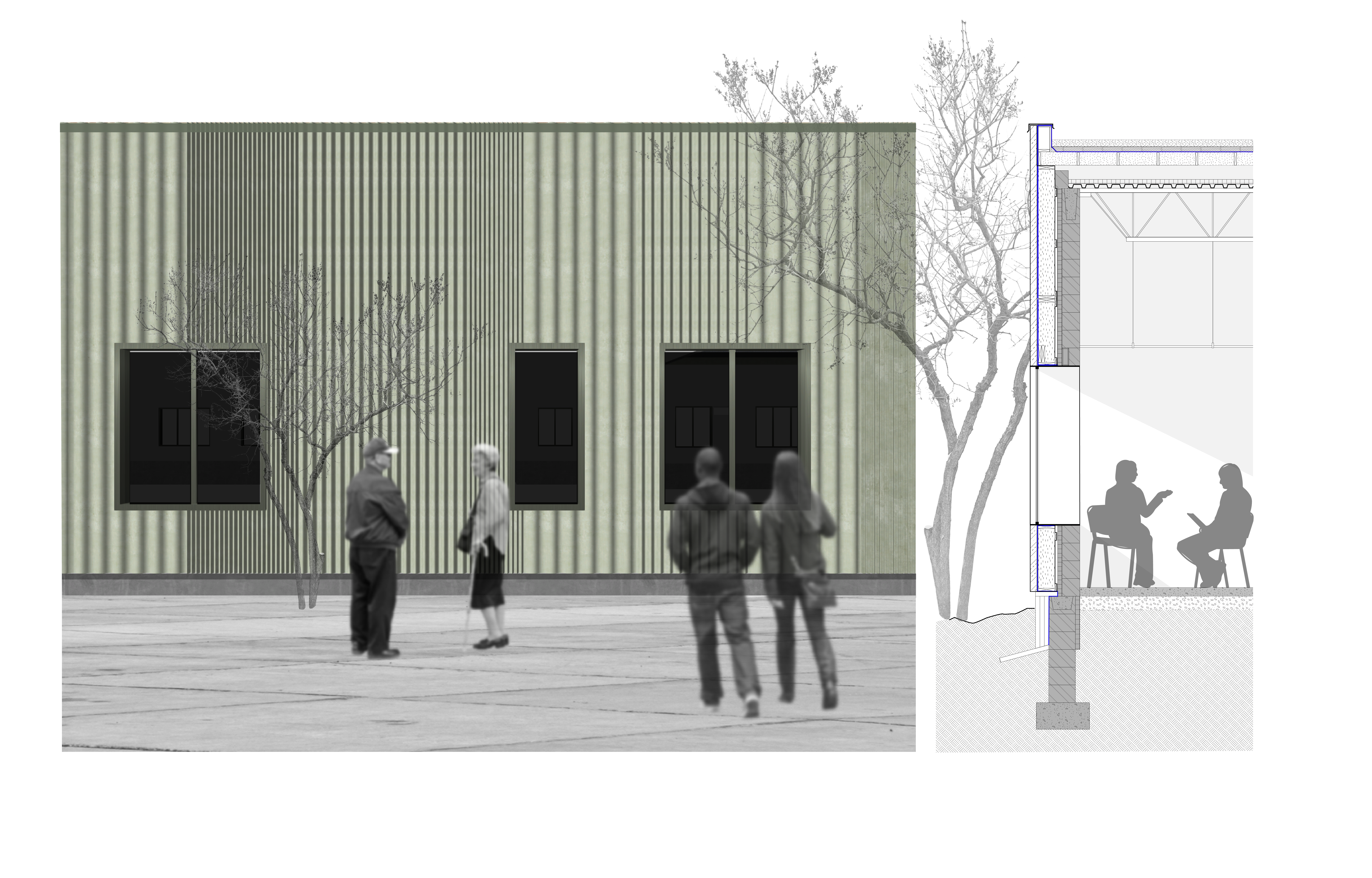

Panelized Solutions

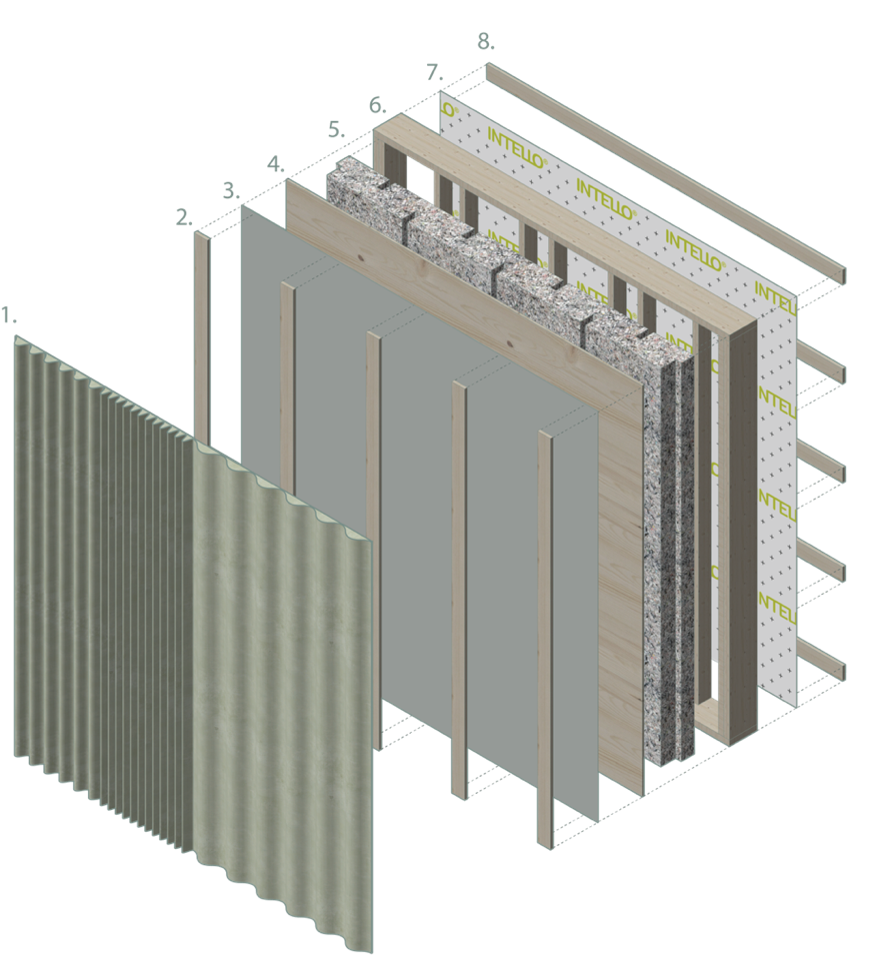

The prototype ReCover panel is a wood framed box which holds carbon storing cellulose insulation. The depth of the frame is flexible depending on the needed performance.

The existing brick will be removed, and panels will be installed in front of existing rigid insulation on the CMU wall structure. A decision can be made when this is exposed whether to install a vapour retarding membrane on its surface prior to panel installation.

The panel components were specified to minimize moisture risks by shedding precipitation on the outside and by promoting drying activity to the exterior through the panel assembly. This is important as the existing assemblies include vapour retarding materials, including polyethylene vapour barrier and rigid foam insulation, which will inhibit drying to the interior of the building. These materials will also inhibit outward vapour drive, from the interior into the panels, however given the age and condition of the building it is highly unlikely that these materials comprise a continuous vapour barrier. The panels are be designed to promote any moisture movement that occurs from the interior to dry to the exterior.

Strapping on the interior side of the panel permits fitting adjustments against the existing walls and provides an internal air cavity that serves as a moisture buffer space for vapour diffusion from the inside to pass out through the panels. The frame backing layer is a “smart” vapour control membrane which varies in permeability depending on the relative humidity of its environment. If moisture is present between the panel and the existing walls the membrane fibers open to let moisture escape. Wood panel framing, plywood sheathing and cellulose insulation are all hygroscopic materials, meaning their fibers transport moisture from areas of higher humidity to those of lower humidity. A vapour-open water-resistive barrier (WRB) protects the outer plywood sheathing and provides a drainage plane behind the rainscreen cavity and metal siding.

PDF of Wall Panel Details | Sketchup File of Wall Panel Details

Embodied Carbon

Embodied Carbon was modeled for the Burlington Seniors Centre NZER scenario in One Click LCA. Materials modeled were based on the most representative materials available to the Canadian market with Environmental Product Declarations (EPDs) available in the One Click LCA database. The analysis was limited to embodied carbon of assembly materials being added to the building including panel additions to above-grade walls, roofs, below-grade components, and windows and doors. HVAC and electrical components were excluded from the analysis.

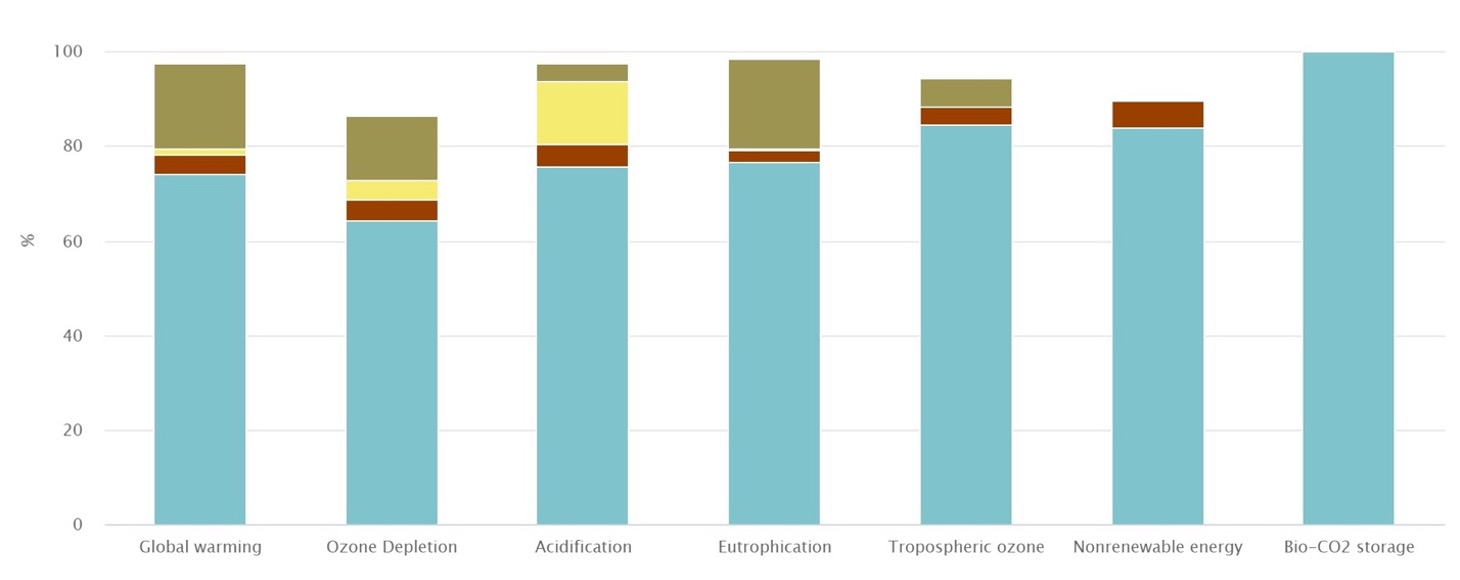

The results include a whole life cycle assessment of the building in six impact categories: Global Warming, Ozone Depletion, Acidification, Eutrophication, Formation of tropospheric ozone, Depletion of nonrenewable energy, and Biogenic carbon storage.

View the embodied carbon graph

Total Cost of Building Ownership (TCBO)

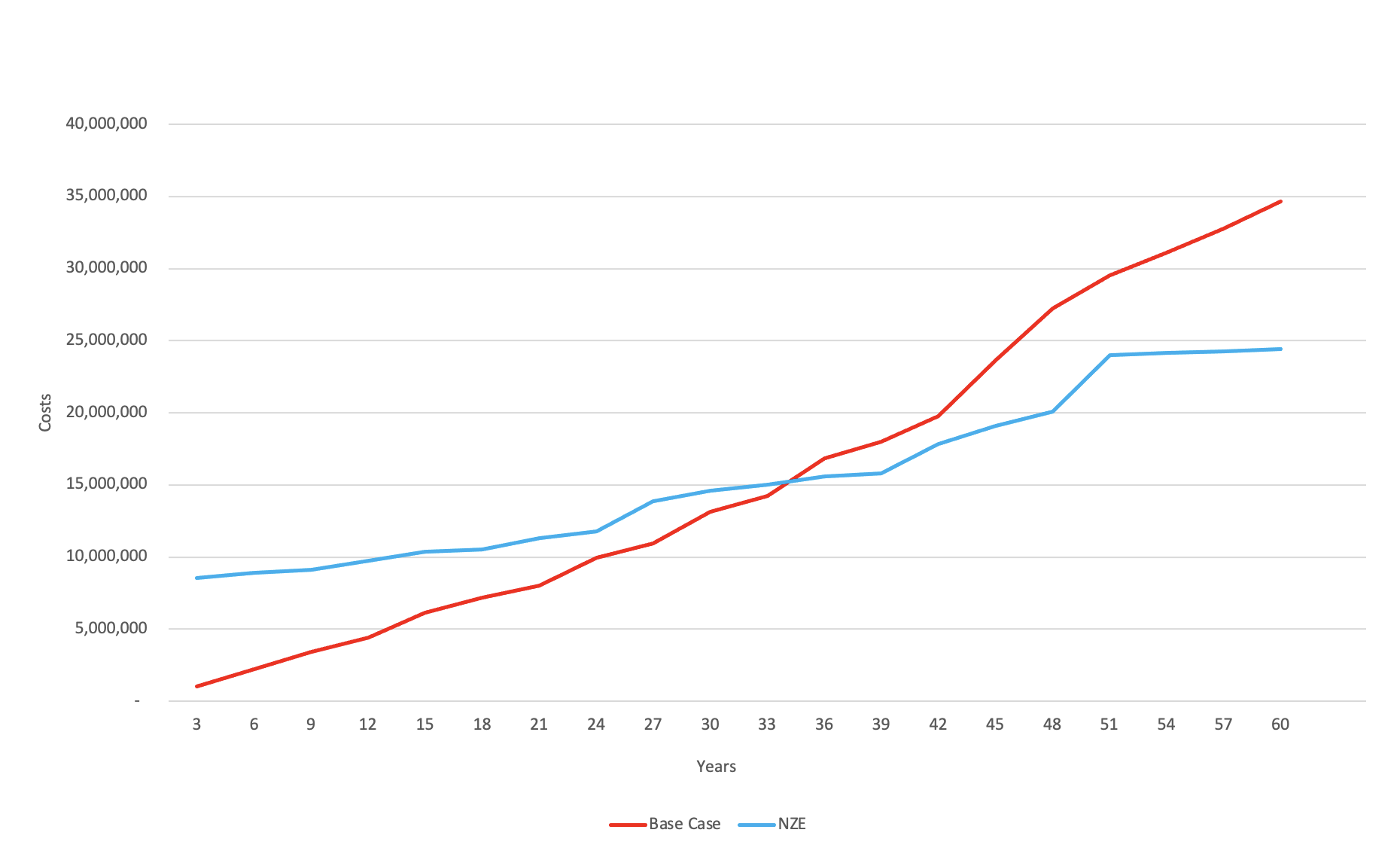

Total Cost of Building Ownership (TCBO) analysis was conducted using the Sustainable Energy Efficient Facility Asset Renewal (SEEFAR)-Valuation© program. Calculations include costs for utilities, insurance, carbon tax, maintenance, maintenance capital (replacing major components as they age out), interest, and escalation of these costs over time. TCBO analysis typically includes property taxes, however the building is not subject to property tax.

Total Cost of Building Ownership Summary

| Base Case | NZE | |

|---|---|---|

| GHG Emissions (kg) (60 Years) | 5,810,144 | 0 |

| EUI (kWh/m²/year) | 435.4 | 0.0 |

| TCBO at 60 Years | $34,646,000 | $24,430,000 |

| TCBO Savings at 60 Years | $0 | $10,216,000 |

| % Diff. from Base Case | – | 29% |

Cumulative TCBO

The lowest TCBO for the Burlington Seniors Centre is the NZE retrofit with a 29% reduction in lifetime operating costs and a savings of $10.2 M.

After 35 years the savings in operating costs from doing the retrofit will exceed the business as usual scenario.

View total Cumulative Total Cost of Building Ownership graph