Access Transit Bus Storage and Dispatch Building – Feasibility Study

This feasibility study, submitted by the ReCover Initiative, outlines a net-zero scenario using a panelized deep retrofit solution for a bus storage and dispatch building in Saskatoon, SK.

| Building Type | Part 3 | Location | Saskatoon, Saskatchewan |

| Year Built | 1970 | Post-Retrofit Total Floor Area | 1300m2 |

Project Team

- Habit Studio ( Designer or Architect )

- RDH ( Energy Modelling )

- M&R Engineering ( Mechanical & Electrical Engineer )

- Stanley Francispillai ( Hygrothermal )

- Seefar Building Analytics ( Financial Model )

- QSolv ( Cost Consultant )

- Fatma Osman ( Embodied Carbon modeling )

- Natural Resources Canada, The Atmospheric Fund, Nova Scotia Department of Natural Resources and Renewables, City of Burlington, Municipality of Colchester, Halifax Regional Municipality, Town of New Glasgow, City of Oakville, City of Saskatoon ( Funder )

Project Priorities

- Reduce Energy Consumption

- Achieve Net Zero or Net Zero Ready

- Reduce GHG Emissions

- Other

Project Goals

The objectives of this study were to de-risk investment in deep retrofits in Canada, to provide evidence on the effectiveness and scalability of a panelized deep retrofit approach and to build confidence and experience in deep retrofits among Canadian municipalities and industry stakeholders.

The goals for the Deep Retrofits explored included:

- Develop a scenario that achieves an Energy Use Intensity (EUI) reduction of 50%.

- Develop a Net Zero Energy Ready (NZER) scenario.

- Develop a Net Zero Energy (NZE) scenario with the addition of onsite renewables.

- All solutions minimize occupant disruption during construction.

- All solutions target minimal embodied carbon.

- Identify the retrofit pathway to the lowest Total Cost of Building Ownership.

- Demonstrate a calculated payback of 20 years or better.

Project Description

Planning the Retrofit

Existing Building Details

Overview

The City of Saskatoon’s Access Transit service provides on demand transportation to people with disabilities within Saskatoon’s city limits. Their operations are based out of two buildings connected via a pedestrian link, located at 422 and 510 46th Street East, Saskatoon. Both buildings are one-storey prefabricated steel structures.

The older and smaller building, on the west side of the site, contains Access Transit’s dispatch offices and a maintenance shop. It is a 1,300 m2 (14,000 sq.ft.) structure built in the early 1970s that was purchased by the City of Saskatoon in 1984. The dispatch office is staffed 24 hours a day, 7 days per week and the maintenance shop operates Monday to Friday from 5:30am to 4pm.

In 2010 the Access Transit bus storage garage was added next door. It was the City of Saskatoon’s first LEED certified building. The 4,423m3 (47,609 sq.ft.) building stores the fleet of 28 lift-equipped buses and contains locker rooms and washrooms for bus drivers, service rooms and zones for refueling and washing the buses. The Access Transit bus storage facility was designed to be 25% more energy efficient than the Model National Energy Code for Buildings (MNECB) baseline and to use 70% less water than a conventional building.

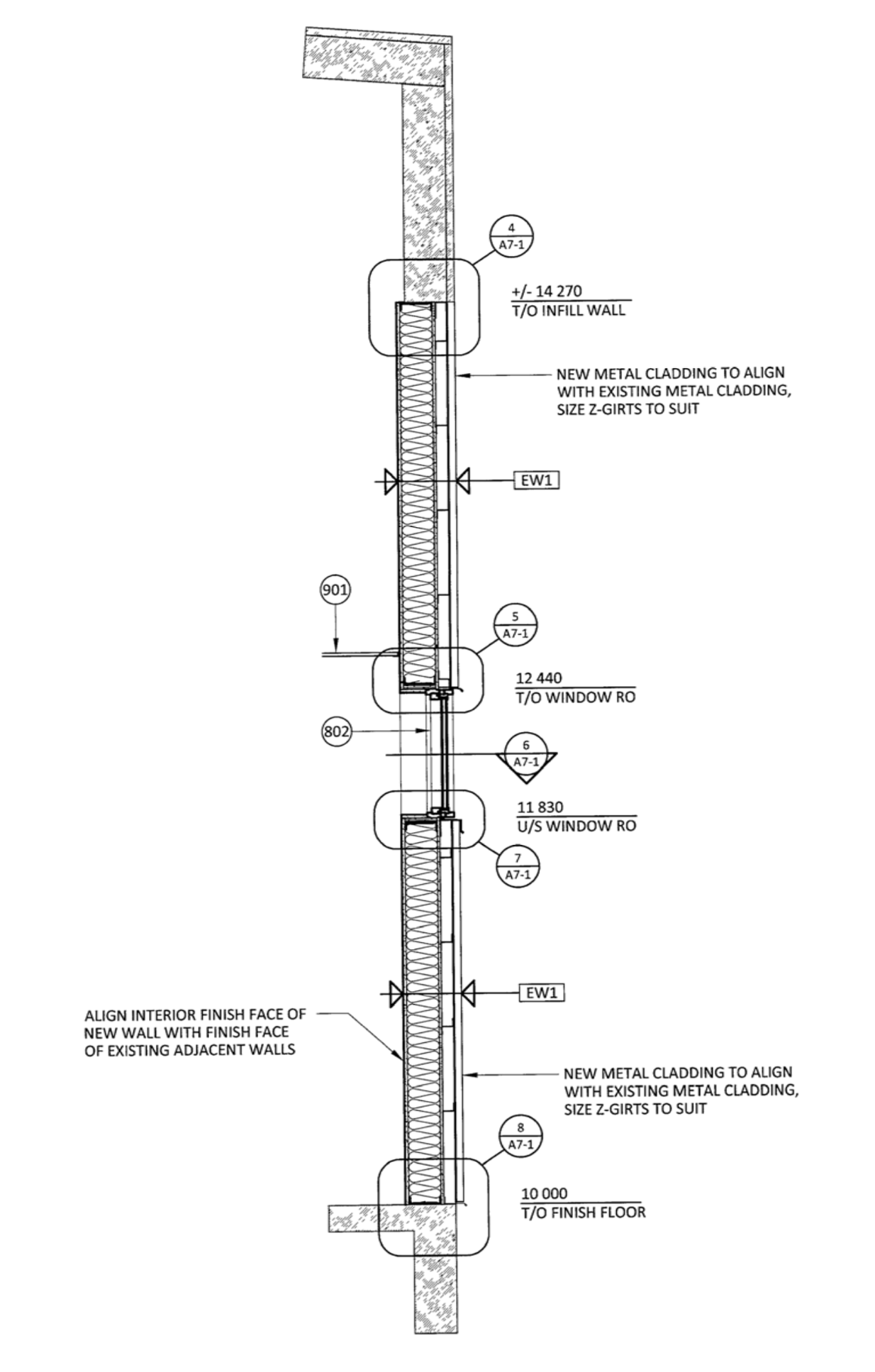

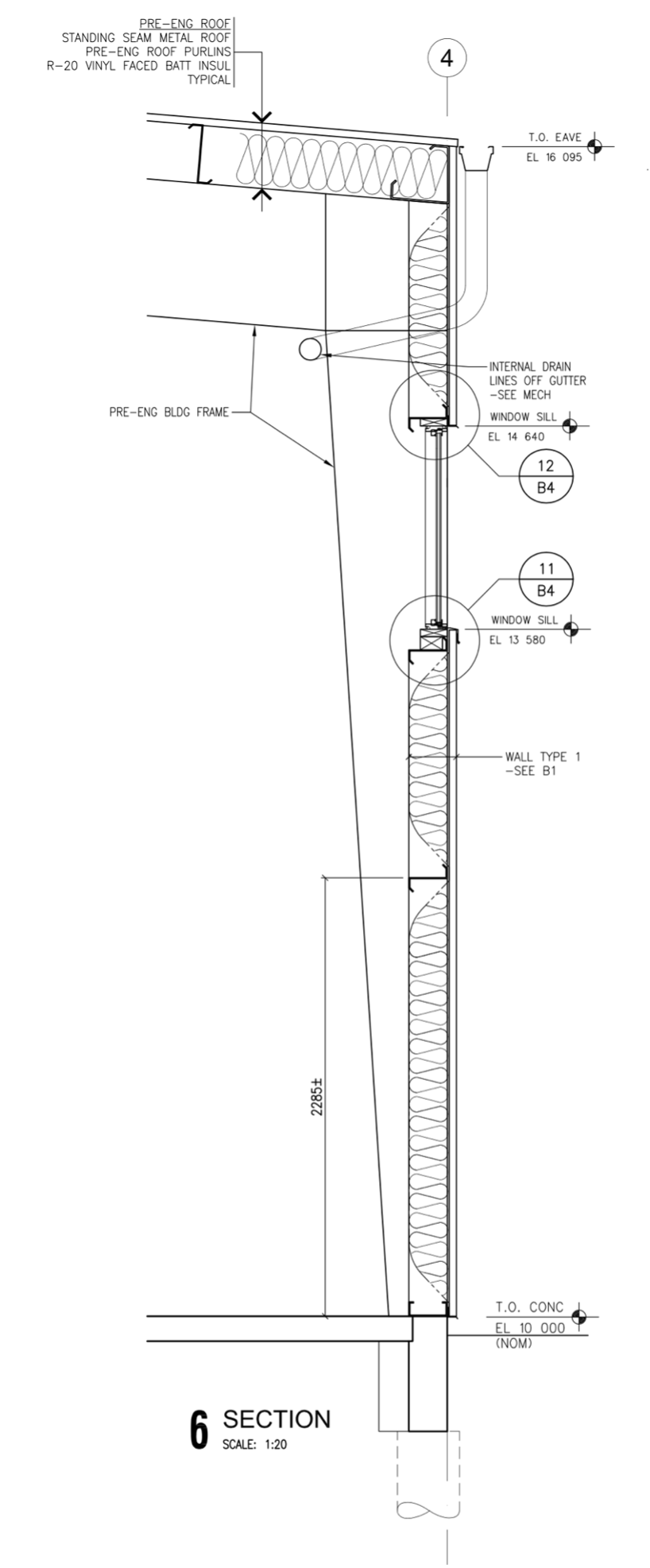

Construction drawings of the bus storage garage were provided to the consultant team for this study. Plans for an internal retrofit to the dispatch office and mechanic, shop completed in 2019, provide overall dimensions and information about some of the building assemblies.

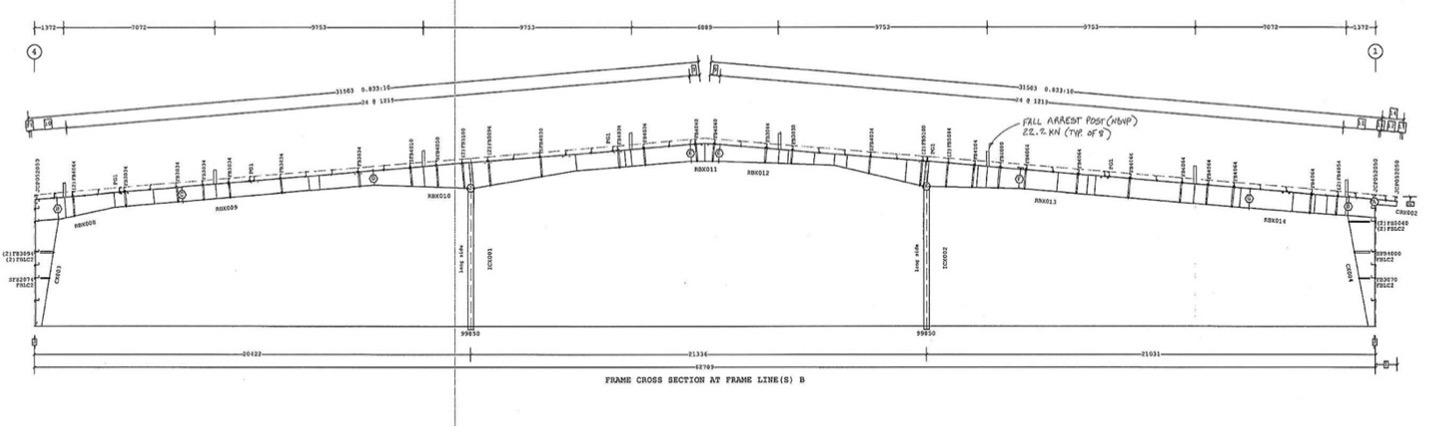

The Transit garage walls and ceiling are insulated with RSI-3.5 (R-20) nominal vinyl faced fiberglass batt insulation. Its north and south walls have an RSI value of 2.1 (R-11.9) and the east and west walls are RSI-2.45 (R-13.9). The roof is RSI-1.76 (R-10). The perimeter of the bus storage garage floor slab is insulated with 50mm of rigid insulation to a width of 3,048mm. The type of rigid insulation used was assumed to be extruded polystyrene with an RSI-1.3 (R-7.5).

The dispatch building walls are also insulated with an unspecified thickness of fiberglass batt. The available drawings do not call out the roof assembly, however based on photos and field observations, the roof is also insulated with vinyl faced batt and was assumed to match the walls for this study. Based on the available drawings the walls and roof of the dispatch building were assumed to be RSI-1.3 (R-7.5). The slab of the dispatch building is believed to be uninsulated.

The link walls are concrete block with 50mm of rigid insulation, RSI-0.7 (R-4). The link roof is wood framed with fiberglass batt between the joists and 50mm rigid insulation, RSI-1.76 (R-10). The link slab is fully insulated with 50mm rigid insulation, assumed to be extruded polystyrene.

Overhead doors make up 21.5% of the wall area in building, representing a significant percentage of the thermal enclosure. The thermal performance of the overhead doors was not found in the available drawings. These were assumed to have a USI value of 1.13 W/m2K.

The primary steel structure of the bus storage garage was designed by Varco Pruden (VP) Buildings. The structure consists of a system of pre-engineered steel portal frames with lightweight steel Z-girts spanning between them. A portal frame is a grouping of columns and beams joined in a simple, structurally efficient form.

The dispatch office and maintenance building is also a pre-engineered steel structure consisting of a system of portal frames connected by lightweight steel purlins and girts. Structural review determined that added loads can be supported on the walls but neither roofs can support added weight. Alterations that increase the thermal performance of the older dispatch office building are also not possible as adding insulation may increase snow loads on that roof.

The walls may undergo a panelized retrofit but is not viable for the roofs. It is recommended that no alterations be completed to either building that would add weight, including a conventional re-roofing with additional layers of rigid foam.

Full Details in the FEED Report

Existing Electrical and Mechanical

| Primary Heat Source | Natural gas furnaces and boiler, electric baseboard, gas unit heaters |

| Heat Distribution | Heating unit, infloor radiant |

| Cooling Source | Condensing units |

| Electrical Service | 800A connection to grid |

| Interior Lighting | LED Light fixtures |

Existing Energy Use (KWH/M2/YR)

| Lights | 16.39 |

| Plug Loads | 22.46 |

| Electric Heat | 0.57 |

| Cooling | 0.25 |

| Pump | 8.33 |

| Fans | 14.36 |

| Natural Gas DHW | 30.55 |

| Natural Gas Heating | 320.75 |

Net Zero Scenario

The design team worked collaboratively to develop retrofit scenarios targeting the project objectives. The analysis assumes a ‘like for like’ retrofit where space usage, occupancy schedules, internal geometry, volume of conditioned space, and window and door dimensions and locations are consistent with existing conditions.

The strategy for building enclosure upgrades is to retrofit the walls with prefabricated ReCover panels. The proposed roof retrofit involves removing existing metal roofing and insulation and replacing it with lightweight vacuum insulated panels (VIPs) and replacing the metal roof.

| Existing Building | Net Zero Energy | |

|---|---|---|

| Effective Wall R-Value | R7.5 and R12.9 | R28.5 and R33.9 |

| Effective Roof R-Value | R7.5 and R10 | R45.5 and R48 |

| Windows | Vinyl, double glazed | Triple pane high performance |

| Air Tightness | 3.0 L/s m² | 0.75 L/s m² |

| Heating Source | Natural gas furnaces and boiler, electric baseboard, gas unit heaters | Ground source heat pumps, booster heat pumps, electric boiler |

| Heating Distribution | Heating unit, in-floor radiant | Ducted AHU and in-floor radiant |

| Cooling | Rooftop condensing unit | Ducted AHU |

| DHW | Natural gas heaters | Heat pump water heater |

| Ventilation Equipment | Makeup air and exhaust units | 90% SRE ERVs with VAV boxes in zones |

| Electrical Service | 800A, 3p | 1200A, 3p |

| Renewable | None | 735 kW |

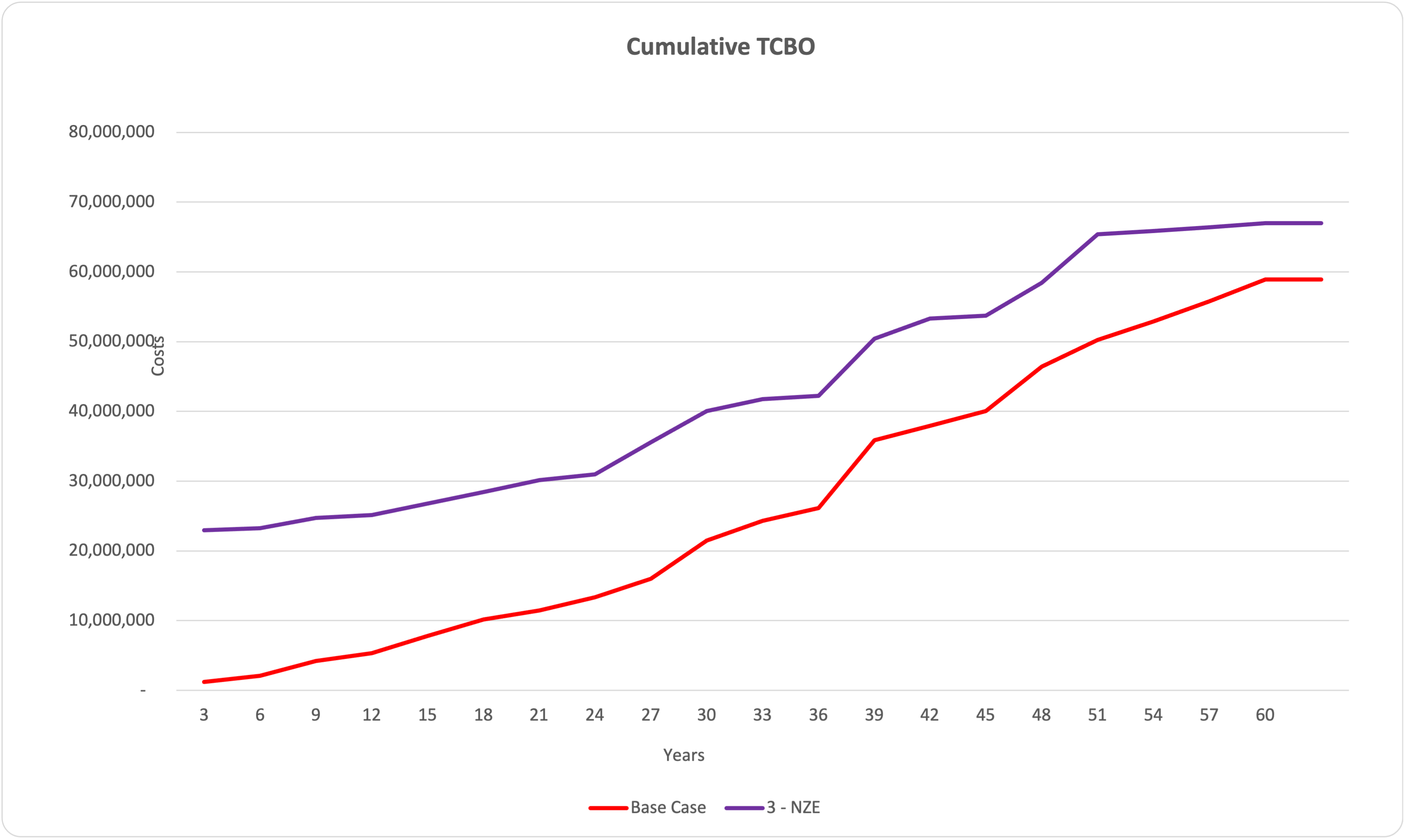

| 60 Year TCBO | $58,883,000 | $66,991,000 |

Full Details in the FEED Report

Panelized Solutions

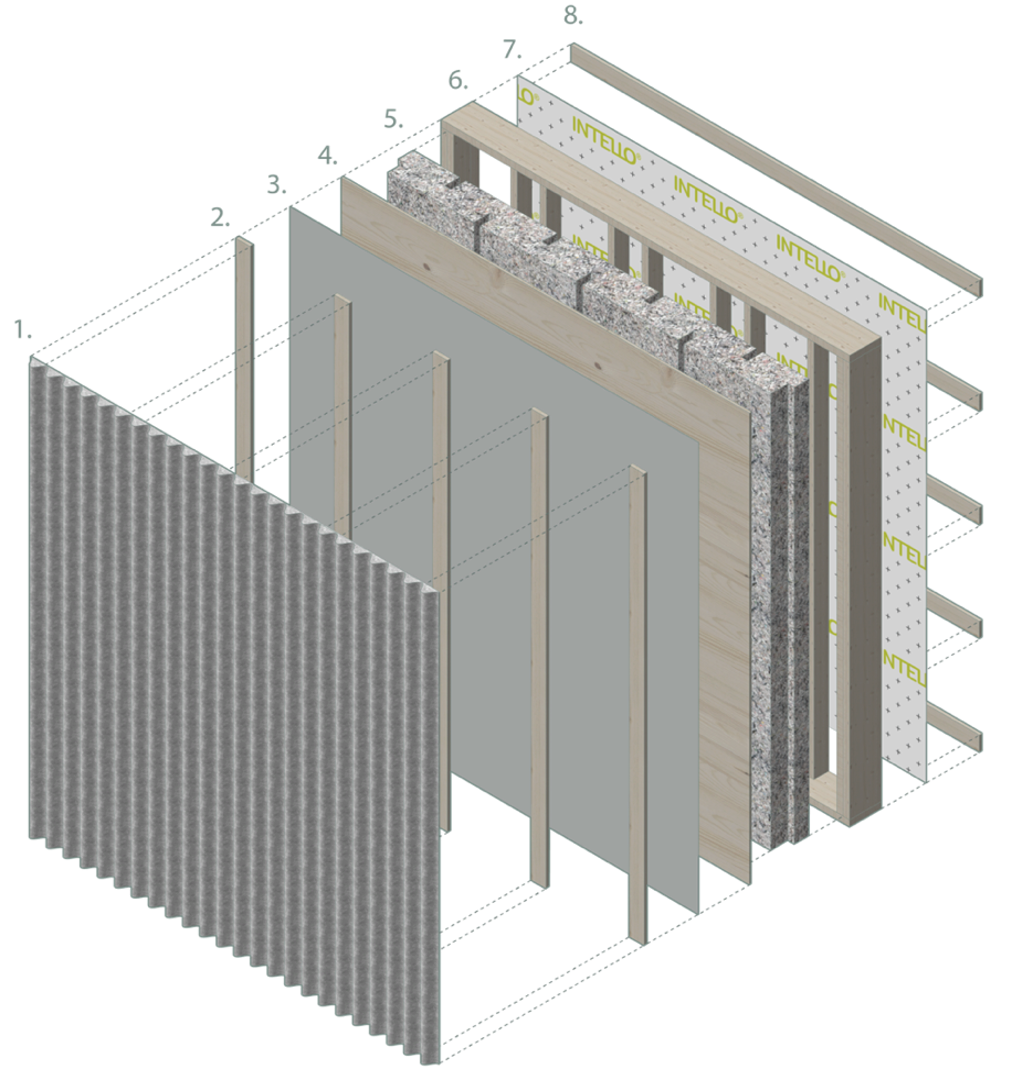

The prototype ReCover panel is a wood framed box which holds carbon storing cellulose insulation. The depth of the frame is flexible depending on the needed performance.

The panel components were specified to minimize moisture risks by shedding precipitation on the outside and by promoting drying activity to the exterior through the panel assembly. This is important as the existing assemblies include vapour retarding materials, including polyethylene vapour barrier and rigid foam insulation, which will inhibit drying to the interior of the building. These materials will also inhibit outward vapour drive, from the interior into the panels, however given the age and condition of the building it is highly unlikely that these materials comprise a continuous vapour barrier. The panels are be designed to promote any moisture movement that occurs from the interior to dry to the exterior.

Strapping on the interior side of the panel permits fitting adjustments against the existing walls and provides an internal air cavity that serves as a moisture buffer space for vapour diffusion from the inside to pass out through the panels. The frame backing layer is a “smart” vapour control membrane which varies in permeability depending on the relative humidity of its environment. If moisture is present between the panel and the existing walls the membrane fibers open to let moisture escape. Wood panel framing, plywood sheathing and cellulose insulation are all hygroscopic materials, meaning their fibers transport moisture from areas of higher humidity to those of lower humidity. A vapour-open water-resistive barrier (WRB) protects the outer plywood sheathing and provides a drainage plane behind the rainscreen cavity and metal siding.

PDF of Wall Panel Details

Embodied Carbon

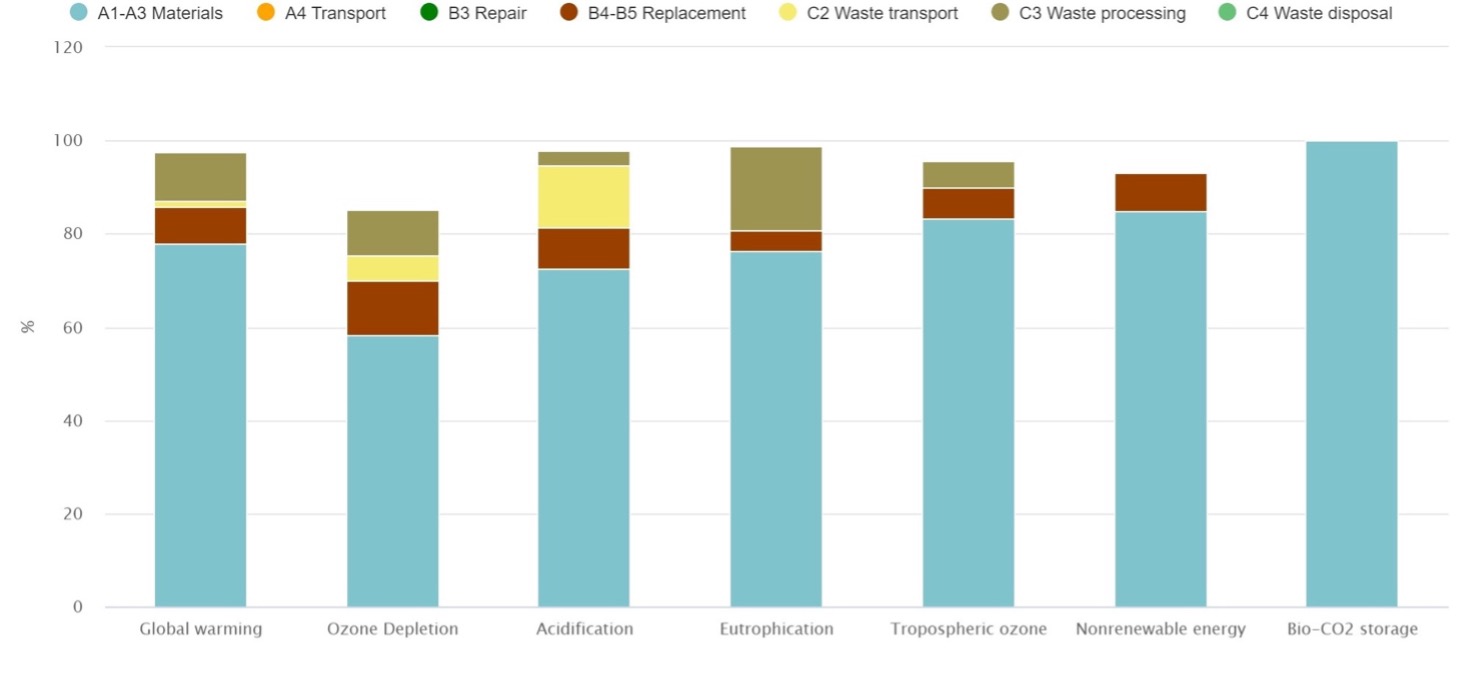

Embodied Carbon was modeled for this project in One Click LCA. Materials modeled were based on the most representative materials available to the Canadian market with Environmental Product Declarations (EPDs) available in the One Click LCA database. The analysis was limited to embodied carbon of assembly materials being added to the building including panel additions to above-grade walls, roofs, below-grade components, and windows and doors. HVAC and electrical components were excluded from the analysis.

The results include a whole life cycle assessment of the building in six impact categories: Global Warming, Ozone Depletion, Acidification, Eutrophication, Formation of tropospheric ozone, Depletion of nonrenewable energy, and Biogenic carbon storage.

| Base Case | NZE | |

|---|---|---|

| GHG Emissions (kg) (60 Years) | 31,531,378 | – |

| EUI (kWh/m²/year) | 413.6 | 0.0 |

| TCBO at 60 Years | $58,883,000 | $66,991,000 |

| TCBO Savings at 60 Years | $0 | -$8,108,000 |

| % Diff. from Base Case | – | -14% |

Full Details in the FEED Report

Total Cost of Building Ownership (TCBO)

Total Cost of Building Ownership (TCBO) analysis was conducted using the Sustainable Energy Efficient Facility Asset Renewal (SEEFAR)-Valuation© program. Calculations include costs for utilities, insurance, carbon tax, maintenance, maintenance capital (replacing major components as they age out), interest, and escalation of these costs over time. TCBO analysis typically includes property taxes, however the building is not subject to property tax.

Full Details in the FEED Report