Prima, Non Ultima

"Prima, Non Ultima" is a deep energy retrofit of a 1937 Charlottetown home, transforming it into a high-performance, Passive House-inspired dwelling with exceptional indoor air quality and drastically reduced energy use. By systematically improving the insulation, air sealing, mechanical systems, and smart electrical infrastructure, the project cut annual energy consumption by over 60% and space heating demand by more than 80%.

| Building Type | Single-Family 2+ Stories | Location | Charlottetown, PE |

| Year Built | 1937 | Foundation Type | Concrete (Full Basement) |

| Structure Type | Wood-Framed | Total Floor Area | 172.6m2 |

| Climate Zone | 6 | Heating Degree Days | 4460 |

| Retrofit Status | Complete | Year Completed | 2024 |

| Retrofit Phasing | No | Geometry Changed | Yes |

| Annual Energy Savings | 244.19% | Operational Carbon Savings | -2.14 tCO2eq/yt |

| Retrofit Type | Envelope and Mechanical | Performance Level | Net-Zero Ready |

Project Team

- Gomex Engineering ( Passive House Designer )

- Homesol Building Solutions ( Energy Advisor )

Project Priorities

- Improve Indoor Air Quality

Project Goals

The overarching goal for the project was to create a model home that showcases that high performance buildings can in fact reduce both operational and embodied carbon while improving indoor air quality with careful selection of healthy building materials.

Following the main priority of improving Air quality of the home, the other priorities were:

- Minimizing embodied carbon of materials used for the retrofit.

- Following Passive House principles

- Avoiding red list chemicals where possible in materials and products utilized

Upgrades

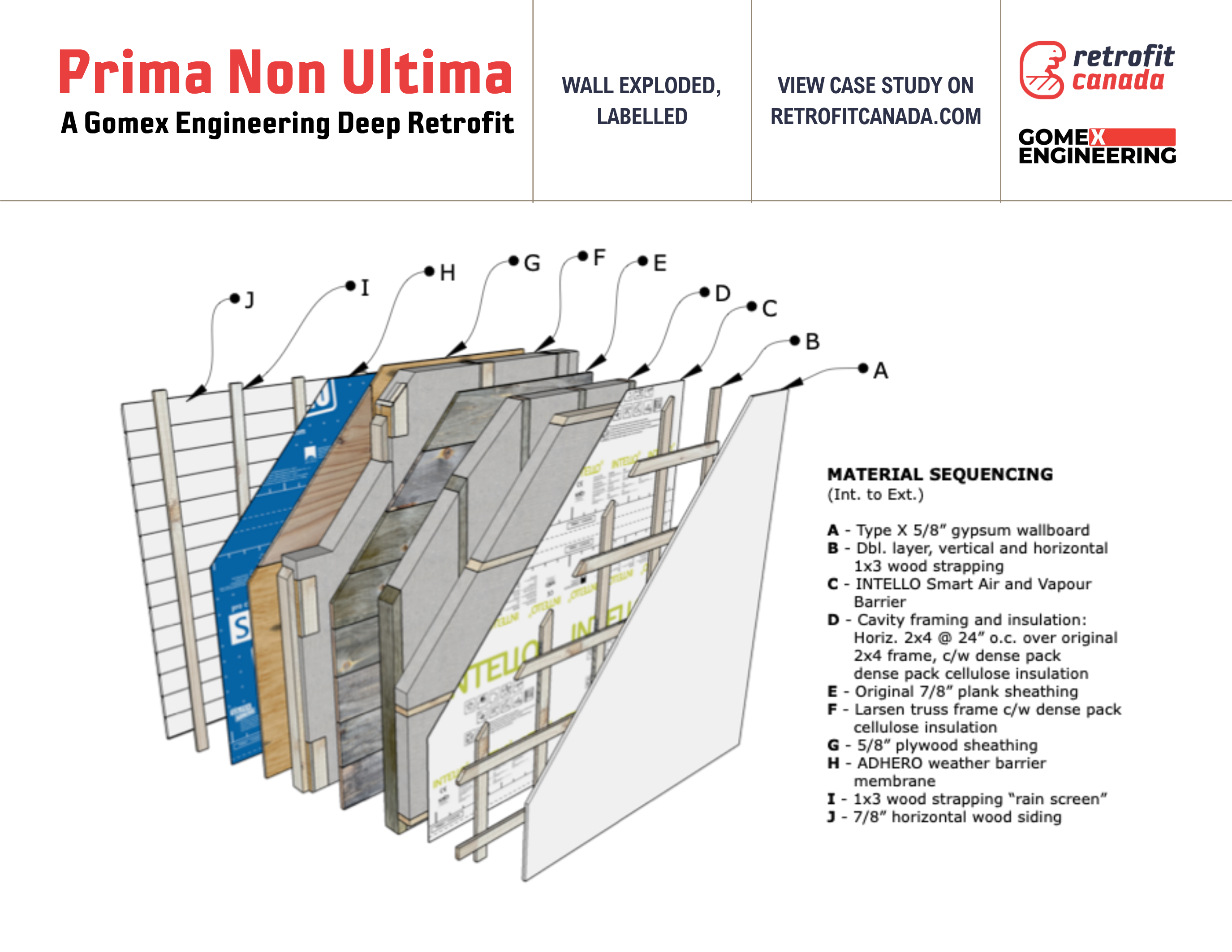

- Modified Larsen Truss added to exterior walls (R-45.5 Nominal)

- Basement ceiling joists filled with dense pack cellulose (R-26 Nominal)

- Existing roof framing filled with 28″ of blown in cellulose, additional 2×4 framing overtop as ventilation cavity with added underlay. (R-102 Nominal)

- Passive House Certified ENERsign Aluminum Clad Wood Windows (U-Factors between 0.22-0.55)

- Passive House Certified ENERsign Doors (U-Factors between 0.11-0.15)

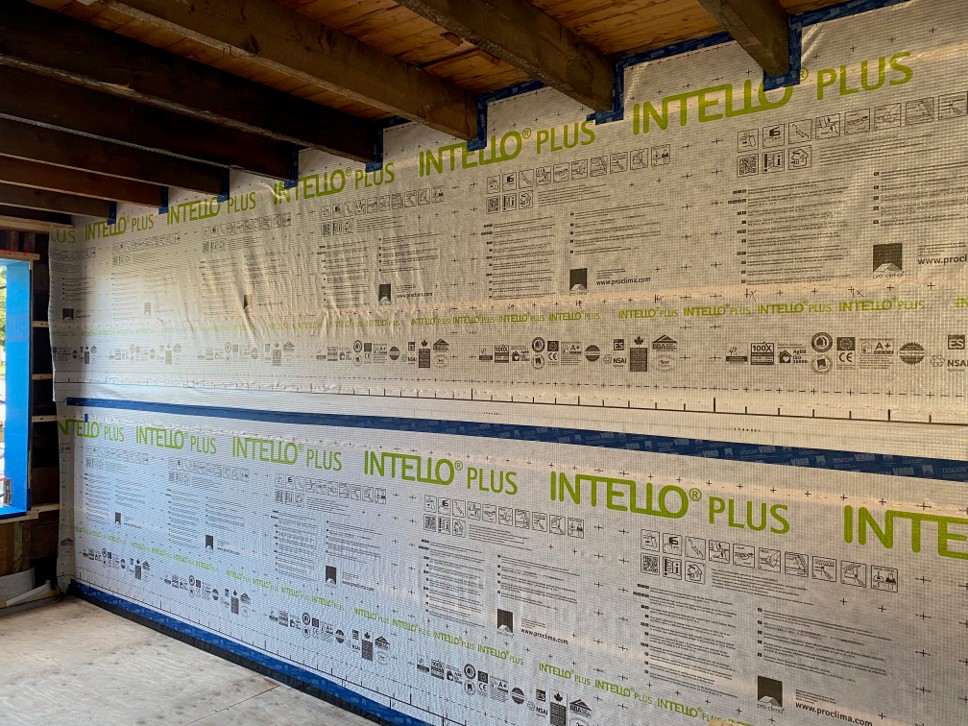

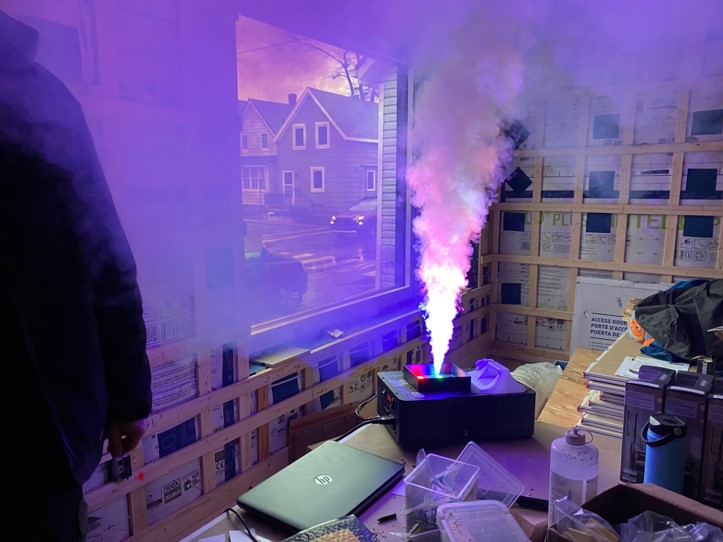

- Continuous Air barrier and improved air tightness (0.57 ACH @ 50 Pa)

- Removal of Oil Furnace, full electrification of mechanical systems.

- Zehnder ComfoAir Q350 ERV and Coway Air Mega 150 HEPA Filtration for air purification.

- Fujitsu 15000 BTU Mini Split Air Source Heat Pump with Convect Air Electric Backup (2 kW)

- 40 Gallon Electric Domestic Hot Water Tank with Drain Water Heat Recovery (DWHR) (46.1% eff)

Project Description

Planning the Retrofit

The retrofit plan for "Prima, Non Ultima" aimed to transform a 1937 wood-framed home into a high-performance, low-carbon, and healthy residence guided by Passive House principles. The approach prioritized exceptional indoor air quality, minimized embodied carbon through sustainable materials, and dramatically reduced energy use. Key strategies included upgrading the thermal envelope with high R-value insulation, enhancing airtightness, installing high-performance windows and doors, and integrating advanced mechanical systems for ventilation, heating, air purification, and humidity control.

Getting to Net Zero

Bringing the property as close to net-zero as possible centered on dramatically reducing energy demand through a high-performance building envelope, ultra-efficient mechanical systems, and smart material choices. Using Passive House-level insulation, a continuous air-barrier, and balanced ventilation, the home minimized heating and cooling loads. Efficient systems like a mini-split heat pump, energy recovery ventilation, and drain water heat recovery were combined with low-carbon materials to reduce both operational and embodied carbon emissions. Finally, a 200-amp electrical upgrade with real-time monitoring and EV readiness ensured the home was prepared for future solar integration if the homeowners choose to do so, making it net-zero ready.

Before & After

General |

Envelope |

Mechanical & Electrical |

Annual Energy Usage |

Carbon Emissions* |

Technical Documents

Videos

Retrofit Canada and The ReCover Initiative hosted Gomex Engineering for a webinar focused on Prima, Non Ultima on Sept 11, 2025..