Project Description

Planning the Retrofit

Solar Home Inc. designed the retrofit to create a net-zero ready envelope that would improve comfort and efficiency, modernize the building’s appearance, and increase property value. Since the homeowners remained in the home during construction, the crew prioritized an exterior-first approach to minimize disruption.

They used a Hydrovac to expose the foundation wall, allowing for the installation of two layers of 2" XPS foam board to the exterior foundation wall, increasing the overall thermal resistance to R-30.

Due to limited attic space, the team applied spray foam insulation to boost the assembly’s thermal resistance and reduce air leakage. They sealed the attic and brought the insulation level up to R-51.

A 2×6 frame increased the above-grade walls to R-30, and older windows were replaced with durable European style windows to future-proof the home.

After the envelope was complete, the final step was designing mechanical systems accordingly to avoid oversizing and short cycling.

Before & After

General

|

|

Before |

After |

Building Condition

|

Before

Original metal siding, mixed windows (some original, others roughly 20 years old), slightly dated appearance. |

After

Hardie board siding, brand new InnoTech window system, modernized and clean aesthetic. |

Envelope

|

|

Before |

After |

Ceiling/Attic Assembly

|

Before

Asphalt roofing material, 3/8″ OSB plywood, 2×4 trusses 24″ on center, R-24 blown-in insulation, 6 mil polyethylene vapour barrier, 3/8″ plywood decking, 1/2″ drywall interior finish. |

After

Original insulation removed and closed cell spray foam insulation added to attic floor with blown in fiberglass insulation on top (totaling R-51 nominal) |

Ceiling/Attic Assembly Effective Thermal Resistance

|

Before

R-23 |

After

R-44 |

Foundation Wall Assembly

|

Before

8″ concrete wall, 3/4″ airgap, 2×4 framing 16″ on center, R-12 fiberglass batt insulation, 6 mil polyethylene vapour barrier, 1/2″ drywall interior finish. |

After

4″ XPS board (R-20) added to exterior down to the footing. |

Foundation Wall Assembly Effective Thermal Resistance

|

Before

R-10 |

After

R-30 |

Wall Assembly

|

Before

Steel siding, 3/8″ OSB sheathing, 2×4 framing 16″ on center, R-12 fiberglass batts, 6 mil polyethylene vapour barrier, 1/2″ drywall interior finish |

After

Hardie board siding, 6″ Roxul rock wool batts, 20 mil SIGA Majvest® 200 Facade Membrane, installed over existing assembly. |

Wall Assembly Effective Thermal Resistance

|

Before

R-12 |

After

R-30 |

Windows and Doors

|

Before

Most windows replaced in the late 90’s early 2000’s, dual pane, Low-E (~R-2.5). A few original windows remained. |

After

New Innotech European style, triple pane, Low-E windows (~R-6) . One dual pane Low-E and one original window remains. |

Air Tightness

|

Before

3 ACH50 |

After

2.06 ACH50 |

Air Sealing

|

Before

Typical for age of home. |

After

Combination of High performance tapes & membranes & house wrap. Spray foam insulation on ceiling decking, spray foam insulation on window frames. Additional framing and siding improvements. |

Mechanical & Electrical

|

|

Before |

After |

Heating

|

Before

Natural gas furnace (Induced draft with pilot, 80% AFUE), Co-Vented with DHW. |

After

2-ton Daikin heat pump (9.1 HSPF), backup resistive electric coil. |

Cooling

|

Before

None |

After

2-ton Daikin heat pump |

Hot Water

|

Before

Natural Gas Storage Tank With Pilot Light (151L, 0.55 EF) |

After

AO Smith heat pump water heater (189L, 0.90 EF) |

Ventilation

|

Before

Naturally aspirated, no whole home system. |

After

Entropy Recovery Ventilator (ERV), 77% Efficiency. |

Renewables

|

Before

None |

After

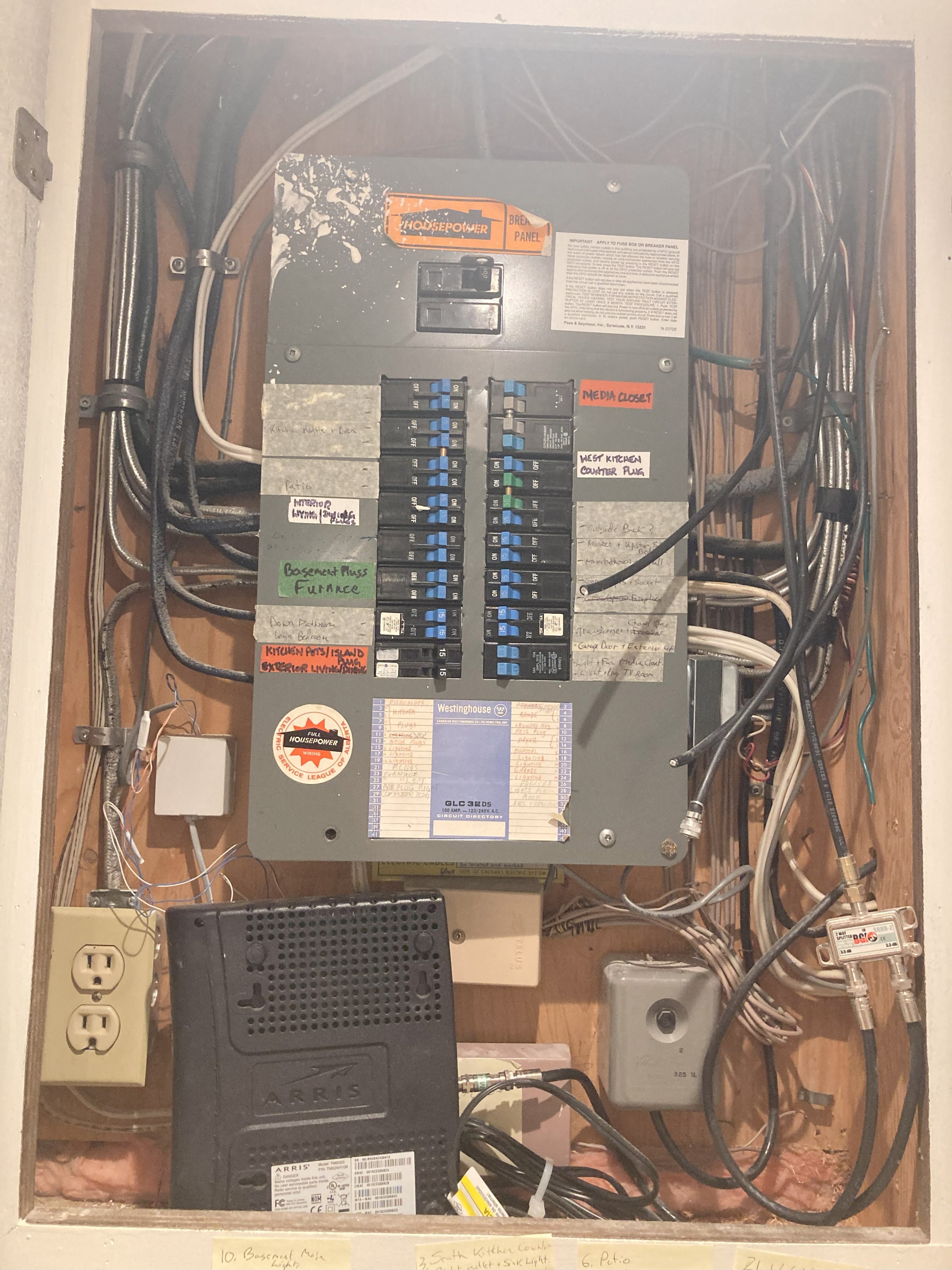

Net Zero ready, Smart Electrical Panel 100A (EV Ready, Solar Ready) |

Electrical Service

|

Before

100 Amps |

After

100 Amps |

Mechanical Other

|

Before

No Data |

After

New 100 amp Genius smart panel installed |

Annual Energy Usage

|

|

Before |

After |

Total Annual Consumption

|

Before

148 GJ |

After

43 GJ |

Total Net Consumption

|

Before

148 GJ |

After

43 GJ |

Energy Use Intensity

|

Before

165.1 kWh/m2/a |

After

47.97 kWh/m2/a |

Annual Heating Demand Intensity

|

Before

107.32 kWh/m2/a |

After

13.91 kWh/m2/a |

Annual Cooling Demand Intensity

|

Before

0 kWh/m2/a |

After

0 kWh/m2/a |

Annual Electricity Consumption

|

Before

7512 kWh |

After

12005 kWh |

Annual Natural Gas Consumption

|

Before

121 GJ |

After

0 GJ |

Light and Appliance Energy Consumption

|

Before

11.84 GJ |

After

11.61 GJ |

Other Electrical Consumption

|

Before

13.32 GJ |

After

13.76 GJ |

Space Cooling

|

Before

0 GJ |

After

0 GJ |

Space Heating

|

Before

96.2 GJ |

After

12.47 GJ |

Ventilation

|

Before

0 GJ |

After

0.86 GJ |

Water Heating

|

Before

26.64 GJ |

After

4.3 GJ |

Carbon Emissions*

|

|

Before |

After |

Annual Operational Carbon Emissions – Electricity

|

Before

3675 KgCO2e |

After

5852.78 KgCO2e |

Annual Operational Carbon Emissions – Natural Gas

|

Before

6364.66 KgCO2e |

After

0 KgCO2e |

|

*Based on emissions values from Canada’s Official Greenhouse Gas Inventory 2022 Emissions Values

|

Photos

Pre Retrofit

During Construction

Post Retrofit