Net-Zero Split-Level

With a comprehensive deep retrofit including a renewal of the envelope, replacement of mechanical systems, and a solar PV installation, this Edmonton home is net-zero.

| Building Type | Single-Family Split-Level | Location | Edmonton, AB |

| Year Built | 1963 | Foundation Type | Concrete (Full Basement) |

| Structure Type | Wood-Framed | Post-Retrofit Total Floor Area | 211m2 |

| Climate Zone | 7a | Heating Degree Days | 5120 |

| Retrofit Status | Complete | Year Completed | 2023 |

| Retrofit Phasing | No | Geometry Changed | No |

| Annual Energy Savings | 102.35% | Operational Carbon Savings | 11.82 tCO2eq/yt |

| Retrofit Type | Envelope and Mechanical | Performance Level | Net Zero |

Project Team

- Butterwick Construction ( Builder )

- KBL Building Improvements ( Builder )

Project Priorities

- Reduce Energy Consumption

- Increase Thermal Comfort

- Reduce GHG Emissions

Project Goals

With this deep retrofit, the family aimed to reduce their GHG emissions, reduce their energy consumption, and increase the comfort and functionality of their home along the way.

Upgrades

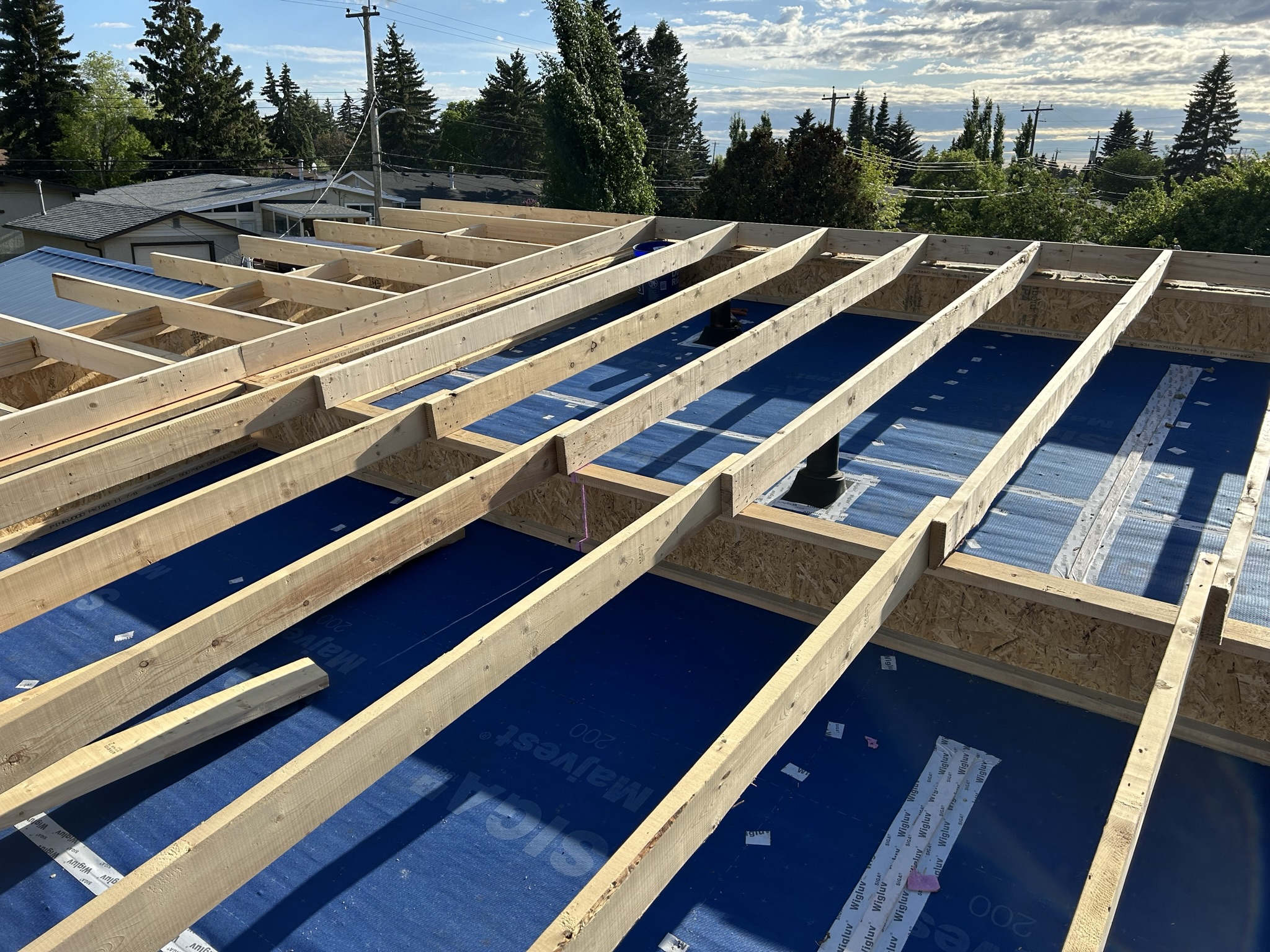

- New roof structure was added on top of the existing cathedral roof to increase insulation values

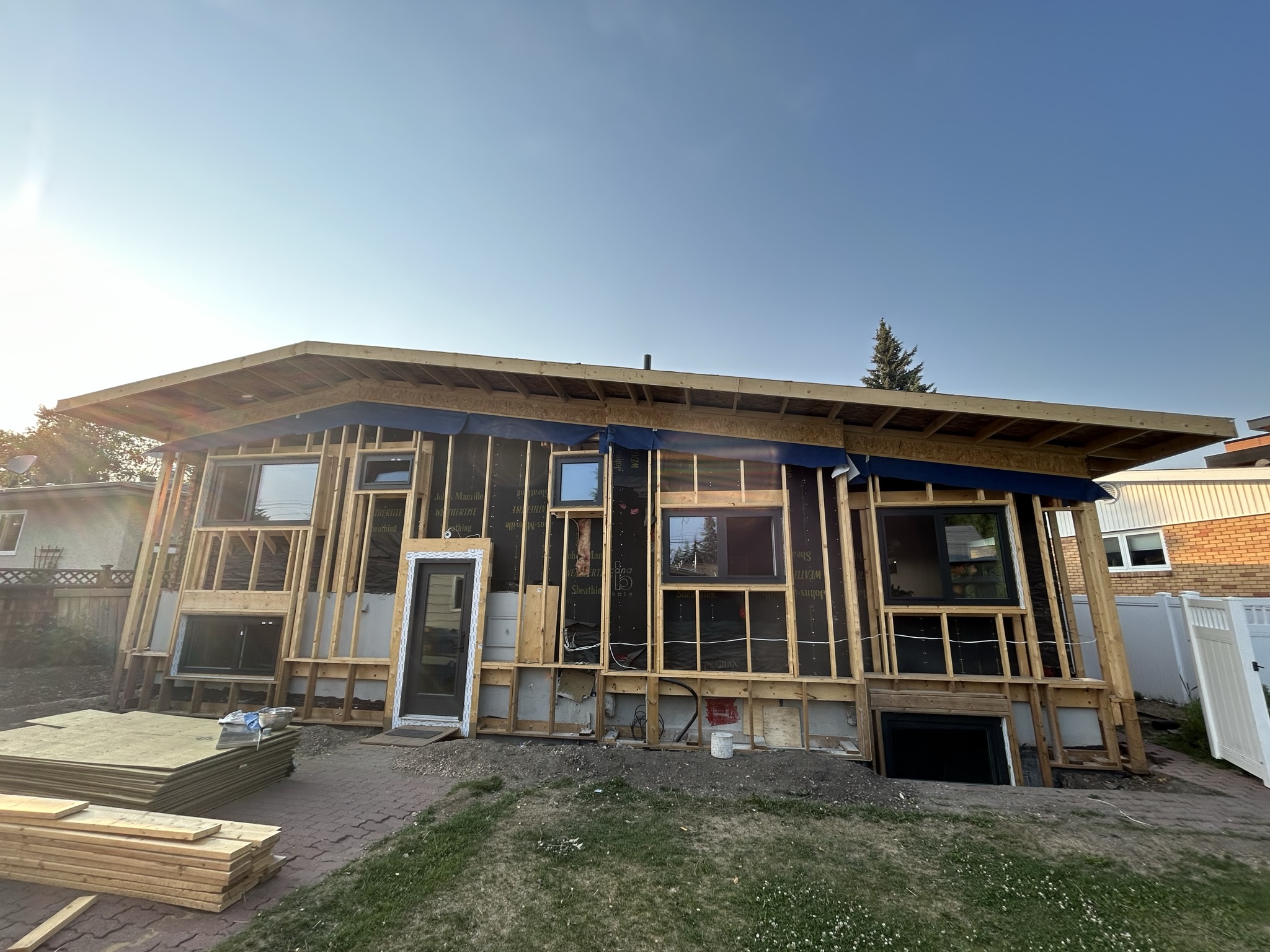

- External main wall insulation upgraded through installation of a modified Larsen truss system

- Exterior foundation insulation added down to the footings

- Windows replaced with triple pane windows

- Continuous air barrier installed

- Gas furnace replaced by an air source heat pump

- Gas hot water heater replaced by integrated heat pump hot water heater

- ERV installed for active ventilation

- Solar photovoltaic array installed

- Electrical service upgraded to 200 Amps

Project Description

Planning the Retrofit

The project team took a comprehensive approach, upgrading the building envelope from top to bottom, replacing mechanical systems with high-efficiency options, and adding solar PV to provide a renewable energy source.

The contractor dug out the exterior of the basement by hand and added insulation all the way to the footings. Two layers of basement insulation were installed: one layer of EPS foam against the wall and another layer of GPS on the outside. The EPS—geo-drain insulation board from Plasti-Fab—had slotted openings near the basement wall to direct water toward the weeping tile. This layer also added a valuable thermal top-up.

The exterior walls were built out using a Larsen truss-style double wall system supported by a box beam. This assembly created space for additional mineral wool batt insulation. Spray foam insulation was used in the box beam to provide both air sealing and thermal protection at the transition between foundation and wall.

To improve the roof, the team built a new structure over the existing cathedral roof. This created space for added insulation and allowed for an extended overhang to match the increased wall thickness. The assembly included TJI Truss Joists and perpendicular 2×6s, which formed both the overhang and an air gap between the insulation and sheathing.

New access paths were created to accommodate electrified mechanical systems, and the windows were upgraded to triple-pane. The building was then wrapped in a continuous air and vapour barrier.

At the same time, the owner carried out additional climate resilience and maintenance upgrades, including new exterior Hardie siding, standing seam metal roofing, and new soffits and eavestroughs.

Before & After

General |

Envelope |

Mechanical & Electrical |

Annual Energy Usage |

Carbon Emissions* |